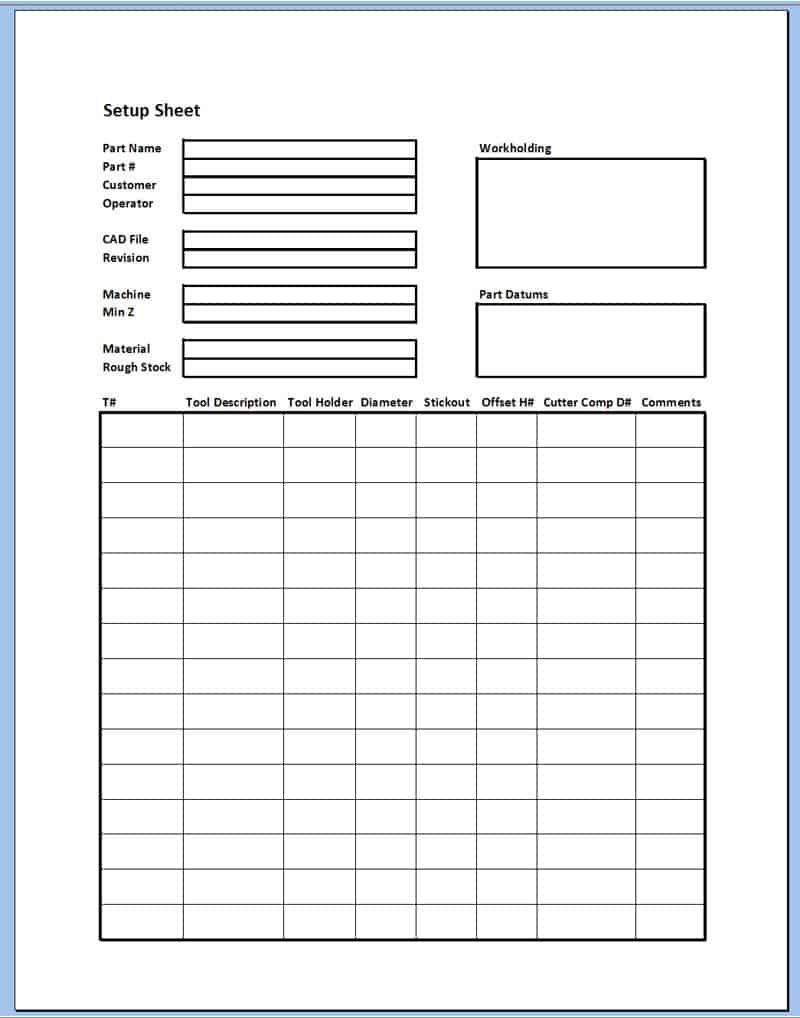

Setup Sheets play a vital role in the daily operations of many machine shops. They guide the operator in setting up the machinery for a specific task. Most Setup Sheets are designed to be simple, making them straightforward to generate and utilize. Here's an example of a one-page Setup Sheet crafted in Excel:

A simple one page Setup Sheet done in Excel. Click the link to download a copy of the Excel file.

Many CAM programs can also be set up to generate Setup Sheets automatically as part of the post. Often they create the setup sheets in HTML and they can be viewed or printed by your web browser.

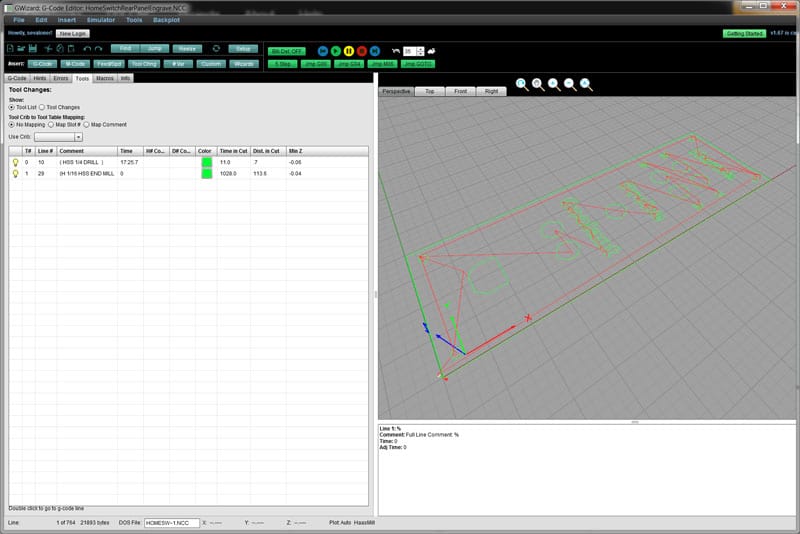

There are certain other tools that can extract information from g-code programs that is useful for Setup Sheets. For example, CNCCookbook's G-Wizard Editor software has tabs that display a variety of information including:

- Tool List: Both the list of tools as well as the list of tool uses. This list has useful information that GWE extracts from your g-code such as how far the tool travels in the cut and how long it is in the cut-those are useful for keeping up with tool life. Another is the Minimum Z for each tool. Note that the Setup Sheet above calls out Minimum Z for the whole program. Min Z info is great for working out whether there's enough tool stickout to reach the bottom of a pocket or how high to run a program to "Cut Air" and prove it out.

- Macro Subprograms & Variables: Every macro subprogram and variable accesses is listed on these tabs. This may help you determine, for example, if there are standard macro libraries that need to be on the machine for the program to run properly.

- Overall Information: Overall statistics such as the overall program run time or the Min Z for all tools is on this tab.

It doesn't take long pouring over this kind of information about a part program to wonder if another purpose of the Setup Sheet is to provide overall documentation. A CAD File, CAM File, G-Code File, and a Setup Sheet might be all we need to fully document a program if there's enough meat captured by the Setup Sheet.

GW Editor's Tool Tab has useful information for Setup Sheet creators...

There are two challenges in adding more information. One is that the information has to come from somewhere, and if it is all manually being generated, that means more work for someone. As mentioned, there is some software that can assemble a lot of information more or less automatically for you. Let's assume you could get software to assemble anything you wanted to make the perfect Setup Sheet. A Perfect Setup Sheet is laid out so an experienced Machine Operator can get Setup and ready to start making parts as quickly as possible without being distracted by unnecessary information. At the same time, the Perfect Setup Sheet would allow drill down to enough additional information that is provides truly excellent documentation for nearly all aspects of a particular operation.

As you may have heard, we're working on a new CNCCookbook product that will be called G-Wizard ShopFloor. At a very high level it's focused on Teamwork. Or, to put it another way, it's focused on helping everyone in your Shop to be as productive as possible while making that added productivity as easy and fun as possible. An important part of all that will be a (ahem) Clean Sheet approach to Setup Sheets. So let's go beyond the simple one page sheet above and talk about some of the things we might like to have in our Perfect Setup Sheet.

Each of the bold faced titles below represents a major section or area of capability. Imagine that you'll have total control over how much or how little of this you see, even my role. For example, it may be the machinist, designers, and/or managers that care about seeing all of the information for documentation purposes as discussed, while Machine Operators only what to see the essentials.

Header

The Header contains all the basic information describing what the Setup Sheet is for and where it came from:

- Part Name & Number

- Customer

- Last Time it Ran, and the ability to find out who ran it in case you have questions

- CAD File and Version Information. You'll want the ability not just to know which CAD File and version, but to pull it down and look at it with a CAD File Viewer. If you're working on designing the part, you'll want to be able to edit the CAD File and make sure everyone has the latest version and not some older version.

- Operation or Work Order Name and/or Number. Most parts need multiple operations that are potentially on different machines. Each Setup Sheet is for one particular Operation, but we'd also like to be able to access the other Operations and see how they go together for a view of the overall process.

- Machine: What machine is this operation expected to be done on?

- Overall Lowest Z

Rough Stock

A description of the rough stock that this operation starts from that tells us the material, dimensions, and anything else we'd need to understand whether the rough stock we're being handed is what the designer had in mind and what will work for this operation. Rough stock could be just a standard material shape with certain dimensions, a casting, or a semi-finished part.

Per Batch Checklist and Data Capture

First, we setup the machine. Then we run one or more batches, each of which produces one or more parts. In between batches, we unload the parts and reload rough stock. The per-Batch checklist is what we do to go from unload to reload to pushing the Green Start button.

- Checklist

- Tool Life and Tool Inspection Info. For example, check Tools 3 and 5 every other batch as their inserts wear quickly.

- Critical Dimensions and Tolerances: Basically, what should we be checking and how often to ensure tolerances for the job will be met. If a tolerance is out, there should be a note telling us what to do about it, such as adjusting a Tool Wear Offset.

- Notes & Squawks: Pilots have what they call "squawks" about their planes where they note any problems that need to be addressed at the next maintenance. Same here. Ideas to improve the operation, trouble spots, and other notes that will go towards either improving the process or making it easier for the next guy go here.

Tool Data

Here, we'll want the usual information that's on virtually every Setup Sheet such as the one above. There needs to be enough there so the toolchanger can be set up from scratch or checked to see that it contains exactly what's expected. In addition, some nice to haves:

- A list of the features from the CAM software's perspective with which tool is used and the expected time for the feature to be machined. You might call this an Operations View of the tooling.

- Information on any special tools.

- G-Code snippet that uses G10 to load Tool Info into the machine's tool table, for example if you're using offline tool setting.

- Digital Photos or CAD drawings of the cutter and toolholder.

- Enough other information so that if we break an insert or damage a tool we can use the information to get back up and running ASAP.

Job one for this section is setting the tools up on the machine. After that we're interesting in managing tool life and replacing tooling as needed.

Fixtures and Workholding

Once the machine has the right tooling in the carousel or turret, the next issue is to set up the workholding. It could be as simple as a milling vise or it might involve a more complex custom made fixture, perhaps a vacuum fixture or some such. Whatever the workholding may be, the setup sheet needs to tell the setup guy what he needs to do to get the fixture onto the machine properly. That information likely includes the following:

- Description

- Setup instructions

- Work Offsets: What kind of work offsets are in use here and how should they be set up relative to the fixture?

- Location of the datums on the fixture: Where is part zero?

- If stops are to be used, how should they be set and used? Lay this out in the description.

- A nice diagram or photo showing how parts are nested together on the fixture where multiple parts are being made.

- Speaking of digital photos, a picture is worth 1000 words and its so easy to take digital photos when every phone is a camera. Consider photos of the fixture installed on the table with no workpieces, fixture with workpieces before any machining, and finished parts picture on fixture. Other useful digital photos include shots that show tricky features on the part or close ups of what the surface finish should look like.

G-Code Information

We're almost ready to make some chips with the tools in the toolchanger and the workholding in place and ready to go, but we need the right g-code on the machine. Consider the following:

- Program Name

- File Name + Possibly Location on the Server where your g-code files are kept

- Revision # or Date

- Programmer

- Targeted Machine & Controller

- Description

- Expected Run Time

- Any Auxilliary G-Code that the program is counting on to be present: standard macro libraries, probing libraries, etc.

Customization: What Would You Add or Take Out?

Phew!

That's a lot of information, but it's potential all useful. What works for your shop will be the tradeoffs between the work required to create the setup sheet and the value of each item on the sheet coupled with what your shop's Best Practices dictate as being important for the setup sheet.

We have come a long way from simple single page Setup Sheets, although they're probably still the most commonly used by far. The potential exists to offer a lot more information.

Tell us more about your Setup Sheets and about what you'd like to see in the future if you could wave a magic wand and have anything:

Take the CNCCookbook Setup Sheet Survey

We'll share the results and hopefully this article and the survey results will give everyone great food for thought on their own Setup Sheets.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.