7 days by cncdivi

My day at the shop was less productive than I would have liked today. Despite spending a significant amount of time, I accomplished very little. The main issue was realizing that I had run out of Argon for my Tig welder and discovering that the supplier of my tank had shuttered their business. Despite my efforts and multiple stops, I still couldn’t find any replacement for the Argon. Interestingly, during the course of the day, I received a message from a regular reader who shared his idea to enhance the productivity in his workshop by arranging some frequently used tools for his Bridgeport mill. Furthermore, I came across a motivational blog post titled, 30 Things to Stop Doing to Yourself, which filled me with inspiration. Considering these, I thought it was the perfect moment to write down this post.

Let’s get our productivity up, people!

1. Don’t put a twist drill back in the index if it isn’t sharp.

It’s nice to start with a sharpened twist drill. Putting a dull one in the toolholder and trying to do a job with it just wastes extra time as you procrastinate about sharpening or replacing it. Drill Bit Sharpeners like the Drill Doctor are cheap and they work–don’t put a twist drill back in the index if it needs sharpening. Sharpen it first. If it’s a lost cause, replace it with the next step up in quality because you’re evidently using that size quite a bit.

2. Stop making so many chips because your rough stock wasn’t cut to size properly before you stuck it on the CNC machine.

Aim to cut it within 0.1″ of what it needs to be. Don’t force the mill or lathe to needlessly turn a 1/2″ of material into chips if that could’ve been avoided at the bandsaw. Consider ordering your rough stock from a waterjet, laser, or plasma shop that can guarantee it is cut properly to size. Several times I have noticed that my shop’s biggest weakness for a particular project was it’s ability to cut the rough stock. Accordingly, I keep upgrading these tools and have gone from a cheap bandsaw, to a nice but relatively cheap carbide chop saw, to occasional use of my plasma cutter, and finally to a really nice older Delta 20″ Bandsaw. Each step up was a blessing for shop productivity. I’ve got no place left to upgrade to except a waterjet, but we can dream!

3. Don’t let your CNC machines stop running any more than you absolutely have to.

There are two kinds of tasks related to setup:

– On-line Tasks are tasks that can only be done while the machine is down, like changing a vise.

– Off-line Tasks are tasks that can be done while the machine is running, like doing Tool Presetting.

Try to minimize your on-line tasks by either making them go faster or switching them to off-line tasks. This keeps the machines running so that both you and the machine can be accomplishing something at the same time.

4. Don’t just shuffle tools around when looking for some other tool, put them away.

If you have to move tools around while looking for something, there’s too much clutter. If you touch a tool while looking for some other tool, don’t just touch it, pick it up and put it away.

5. Don’t get a whole ton of nifty storage and then leave it without labels.

How often do you walk up to your rolling toolchest only to open and close several drawers before you find what you’re looking for? Label the drawers. It’s very easy to do with a label making machine. Same thing for any kind of bin storage.

6. Don’t wait for things that are cheap, commonly used, or showstoppers to run out before you buy more.

When I buy fasteners, I don’t just buy enough for the job at hand, I buy a full box in the size needed. Argon was a show stopper for my Tig welding, and I’ve been doing more of it lately. I should’ve checked the pressure gage and made arrangements to refill the tank much sooner. If I order a tap or endmill in a common size, I never order just one. I get 3 to 5 of them. Since I have more than just the few I absolutely need, whenever there is a good sale I go check my common sizes and replenish them at the sale prices.

7. Don’t scatter tooling that is needed together all over the shop.

If I buy a tap, not only do I buy more than 1, but I will also buy a couple of twist drills in the most useful thread % size for that tap. When the taps and twist drills arrive, I have my fasteners in multi-compartment storage boxes. I put the tap in with the fasteners of the same thread size. Now I have fasteners, tap, die, and twist drills all in the same kit. I pull it out, do the project, pack it up, and put the kit back.

8. Don’t spend time changing discs and other attachments on hand power tools just because you’re too cheap to buy more tools.

I like air tools, but I also have some electric die grinders. On the air tool front, I have a bunch already set up with things like Scotch-Brite discs, abrasive cutoff wheels, and deburring tools. On the grinder front, I keep them all set up with wire wheels, abrasive cut off, and flap wheels. If I did more fabrication, I would keep separate grinders by material type so as not to contaminate things. One set for stainless, one for steel, etc. I first saw that trick on a Keith Fenner video.

9. Don’t be scratching around the shop wishing you had a pen and some paper to write on. Buy a box of Sharpies, a box of Steno pads, and a couple of cheap calculators and spread them around the shop

I hate running around looking for a pen or a scrap of paper to write on. Years ago I bought a box of Sharpie markers, a box of Steno Pads, and two cheap calculators–this is a cheap investment at Staples or your local equivalent. My shop has two rooms and I make sure one calculator is in each room somewhere. The Sharpies and Steno Pads are scattered around wherever I’m using them. It’s been years and other than having bought a second box of Sharpies, I always have pen, paper, and calculator handy.

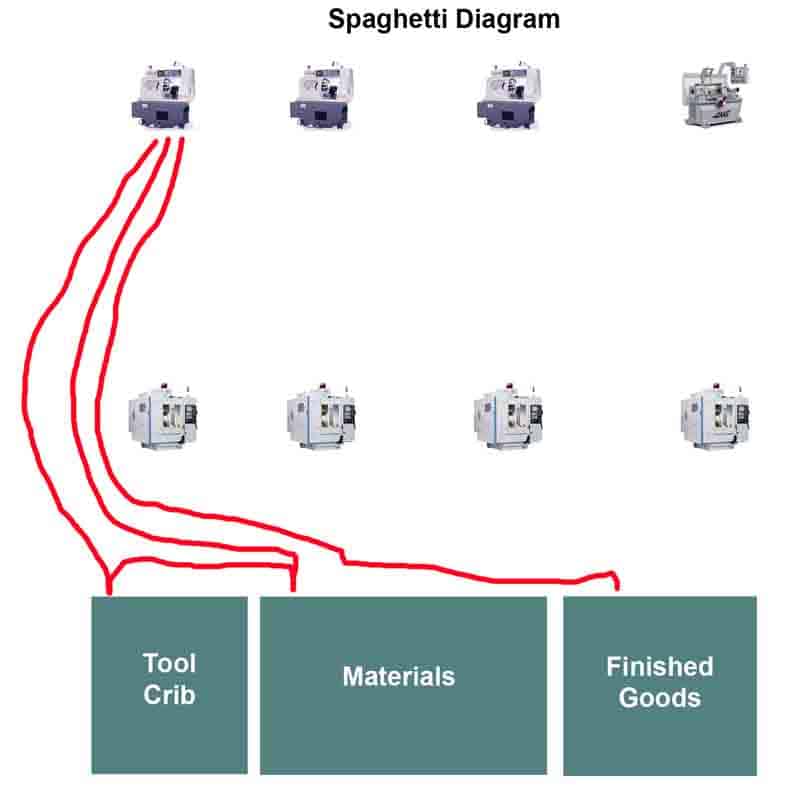

10. Don’t stand there scratching your head and wondering which corner of your shop to even start looking in.

All my rolling tool cabinets are together. All my metrology gear is together near the surface plate. All my lathe tooling is right together. All my cutters (my little Tool Crib) are together. All my mill tooling is together. All my air tools are on a rack together. All my electrical power tools are on a shelf together, except the hand grinders, which are over by the air tools and closer to the welding. All my welding gear is together. Everything I use with my hydraulic press is right next to the press. All of my lifting and rigging slings, chains, ropes and straps are together. All of my fasteners are together. All of my bearings are together. All of my sandpaper is together. All of my painting-related materials are together.

Get it all together. You may not have a box, pocket, or drawer for each individual item, but at least get them all piled in the same place together. And, if you see something similar but not quite like what you’re searching for, at least you know you’ve found the right neighborhood for a deeper search.

11. Don’t squeeze by with sub-par tools that make the hard jobs even harder

I’ve always got a bigger hammer, and if I use it, I go out and look to buy an even bigger hammer next time I am at the tool store. Instead of a breaker bar I bought a long handled 3/4″ ratchet used and a 1/2″ ratchet adapter for it. It’s amazing how much better it works than a breaker bar on a 1/2″ ratchet. If there is a tool designed to give me more leverage in a tight spot, I tend to buy it.

12. Don’t be afraid to buy a tool that makes common jobs faster.

There’s nothing hard about tramming a mill head, but I have a fetish about tramming mine often. So I bought one of those dual indicator gizmos. Is it a gimmick? Sure, but it saves me a little time compared to sweeping the same indicator around and craning my neck so I bought one and I like it. I’ve also got a special rig on a QCTP for lining up my 4-jaw chuck a little faster. It’s nothing special, it’s just that it is an indicator stuck in a QCTP so I don’t have to assemble anything or try to scavenge an indicator. I just pop it on the Tool Post and start setting up the 4 jaw.

13. Stop guessing whether your feeds and speeds are right or trying to tell by ear.

You knew I had to bring this up sooner or later, right? Feeds and Speeds are a science. There’s no place for guessing. Get it right using software like our G-Wizard Calculator or some other software of your choice. Few things will ruin your tool life, surface finish, or machine productivity faster than using the wrong feeds and speeds.

14. Stop thinking you’ll remember to fix that problem, buy that supply, or undertake that project.

Pilots have what they call a list of “squawks” that they carry in every plane they fly. The squawks for that plane remind the pilot and the people maintaining the aircraft what needs to be done or what he heard or felt that might be indicative of a future problem. Don’t let this stuff build up–take one of those steno pads and one of the Sharpies you bought and make a squawk list for your shop. Hang it on the wall. Let everyone using the shop add things to it. Then, any time you have a little extra time (off-line time while the machines are running) or you need to order from a supplier or you hear about a good sale, take down that squawk list and see what you can knock off of it.

15. Stop running from your problems.

Do the hard stuff first. You know you need to. Imagine doing all the easy stuff first, and that adds up to a lot of work, then you do the hard thing and you scrap the part. Now you wasted not only the work on the hard stuff but also the work put into the easy stuff. Do the hard stuff first!

16. Stop dodging the stuff you’re not good at.

Beginners hate 4-jaw chucks because they’re no good at setting them up. It’s frustrating. Here’s a tip: drive right straight at whatever is frustrating you every chance you get. Throw that 4-jaw on the lathe instead of any other chuck until dialing it in is second nature. Tram your mill head and vise every morning until tramming is second nature. Whatever it is, you need to do more of it, not less.

17. Stop the Busy Work.

You know what I mean. You go down to your shop and putter around for a couple of hours and when you’re done you haven’t accomplished a darned thing. There’s endless things you could do that feel like progress of a sort but aren’t. Keep a prioritized list which I’ll call a Backlog that calls out everything you need to get done. Force it to be in strict priority order and don’t do any work on anything but the item on top until you can do no more on that top item. Only then are you allowed to do something at a lower priority.

18. Stop complaining and get inspired.

Somewhere someone is having a good time doing whatever it is you’re complaining about. When I got done having a bad day and left with no Argon bottle, I went and watched a couple of YouTube videos of people doing cool things with Tig Welders. It reminded me I needed to jump back on that horse and go get some Argon. There is so much inspiration out there, don’t let the negative thoughts take hold, go out and get some of that inspiration for yourself.

19. Stop acting like you know it all or like you don’t know anything and go learn something new.

Everyone should always be learning and improving. Whatever you think you’re the expert on, go do some research in your spare time about how to push that envelope. Whatever you’re feeling like an uncomfortable beginner about, dig into that with gusto and learn what the experts know. It’s all out there for you to pick up. All you have to do is want to go get it. If you get tired of that, go teach someone something or get them to teach you something. Nothing like trying to communicate between teacher and pupil to flush out some real learning opportunities.

20. Quit using those manual machines–they’re the most expensive machines to run in your shop.

A machinist friend let me in on a little secret when I was visiting his shop recently–your manual machines are the most expensive machines to run in your shop. This is true because they require constant supervision. You can’t just press the “Green Button” and walk away. And let’s face it, people are the most expensive thing in your shop.

Yeah, I know, it’s so fast to through a piece of stock in the chuck and turn a little bushing. But why can’t that be as fast or faster on the CNC too? Is it because you think you have to make a CAD drawing of the bushing and then run it through your CAM software to get g-code? If so, you’re not doing it right. Learn the basics of g-code well enough that you’re an MDI whiz. MDI (Manual Data Input) is where you type in g-codes and the machine immediately executes them. Once you learn it, your CNC is like a manual machine with DRO’s and Power Feeds on every axis. Except, it’s even better, because it can do arcs, canned cycles, and all sorts of other stuff that’s a real pain on the manual machines.

The only time to be using a manual machine is when all the CNC’s are busy and there isn’t a thing you could be doing off-line to get the machine going again sooner once it stops. If the CNC machines are always busy and you’re spending a lot of time on your manual machines, maybe its time to look at replacing that floor space with an older CNC. They can be had pretty cheap and with a lot of life left in them.

Bonus #21: Stop and contribute something to this list in the comments!

You’ve had unproductive days too, I know it. Tell us what you needed to stop doing to make the day more productive. Tell us how you’re going to get ahead next time so we can all profit too!

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Recently updated on April 12th, 2024 at 08:14 am

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![G-Code Macro Programming for CNC [ Productivity Power Tool ] macro programming for CNC](https://www.cnccookbook.com/wp-content/uploads/2017/10/CNCMacroProgrammingEvolution.png)

I am awed by how clearly you write- as though you are standing there explaining theory, process and execution. It’s laughable to think that some people have disdain for ‘working class’ who are advanced in many areas, as you obviously are.

(spell-check: throw, not through) 😉

Take the time to really study your print. Try and have your workholding solution planned out and take the time to consider the best course of action. I see newer guys really struggle with this bc of pressure from the bosses. Five extra minutes with that peony might save you hours in the long run.

Thank you sir for another great article.