Metal Swarf Meaning: What is Metal Swarf and Chips?

In metalworking, metal swarf refers to the leftover metallic chips from machining. The term "swarf" has an interesting history. In Middle English, "geswearf" means "iron filings" or "rust." In Old Norse, "svarf" means "metallic dust." In Proto-Germanic, it means "shavings" or "that which is rubbed off," as well as "to mop, wipe, or rub off."

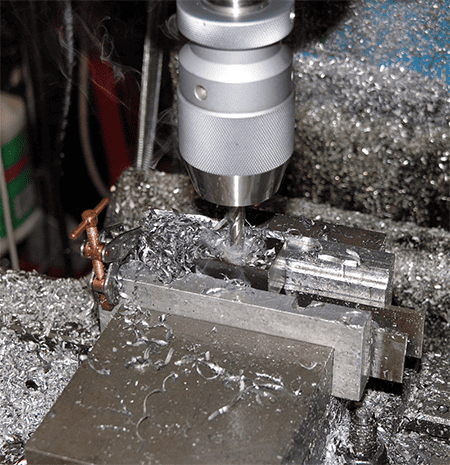

There are various kinds of machine swarf based on the manufacturing process that made the swarf.

- Fines and Filings are the tiniest flecks of material that most often come from grinding tools.

- Shavings range in size from the powder up to larger chips your cutting tool slices from a piece of metal. These are typical Milling Chips.

- Turnings are the result of a turning process. Depending on the material, they can be long curly-cue shaped strips of metal.

Typically, swarf is regarded as a waste material. So, it is something you need to figure out how to dispose of.

Hazards of Coolant and Machine Swarf

Health and Safety Risks

If we're talking about swarf, and the manufacturing processes that produced the swarf involved coolant, than by definition that swarf will be soaked in the coolant. Therefore when considering hazards, we have to consider hazards associated with both coolant and swarf.

Starting with the coolant, we know that contact with many metalworking fluids can cause irritation to the skin, eyes, nose, lungs and throat.

The dangers of swarf are a little more direct since the metal shavings can consist of razor sharp shards of metal. Whether we're talking about needle-like swarf causing puncture wounds, thrown swarf (material removed and thrown by the machine tool) causing shrapnel injuries, or ribbon swarf just straight up cutting into flesh, these are all hazards found when handling swarf.

Fire Hazards

In some cases, we may be dealing with fire hazards. In the case of coolant, straight oil-based coolants are the most combustible. Swarf can also be highly flammable because of its high surface area. Be especially cautious of metal chips consisting of iron, titanium, calcium, magnesium or other reactive metals. Worse, swarf stored in bins may even spontaneously combust, particularly if covered with metalworking coolants.

Other Hazards

If you're working with radioactive metal waste, you'll need to consult with appropriate resources to find the best safety measures to use there.

Safety Measures

To start, always be informed of proper operating and maintenance procedures for your machinery.

Personal Protective Equipment (PPE)

You may want to use appropriate protective equipment depending on the nature of the Sward and Coolant you'll be dealing with. PPE includes protective sleeves, protective goggles, chemical resistant clothing or aprons, gloves and safety shoes.

Keep in mind that you may only wear some of that PPE when directly dealing with the swarf, but not while using the machinery. Gloves are generally a bad idea around rotating machinery, for example.

Fire Prevention

Make sure your facility is set up for fire prevention and that you have proper fire extinguishers on hand that are designed to handle metal fires.

Air Cleaning Systems

Air Cleaning Systems can be helpful for keeping mist out of the shop air.

Cleaning Swarf from the Workpiece

Once the machining cycle has finished, it is important to clean the swarf from the workpiece. This is most commonly done using an air gun. But another more automated approach is to use a chip fan.

Cleaning Swarf from the CNC Machine

Periodically, it's important to clean the swarf from the CNC Machine as well. Depending on your CNC Machine, methods for doing this will range from manual brushing and air nozzle work, to coolant washdown, to automated mechanisms like chip augers and conveyors.

Chip Augers and Conveyors

Chip Augers are powered auger screws that move swarf out of the machine enclosure. A chip conveyor is used to elevate the chips extracted by the auger so they can be deposited in a bin. Typically a 55 gallon drum may be used to store the machine swarf.

Coolant Washdown for CNC Swarf Removal

CNC Machining is a messy process. Chips are thrown everywhere and generally stick to the machine enclosure wherever they land. Coolant Washdown is an option that uses the flood coolant system to wash the chips off the enclosure so they can be picked up and carried away by the Chip Auger.

Recycling Swarf

Many types of swarf can be recycled if proper care is taken. The benefits to recycling swarf are that it adds cash back to your operation, it reduces negative impact on the environment, and it can keep your workspace clean and more efficient.

At the very least, it can be helpful to recycling if you segregate your chips by material type.

At the most, your firm may be ready to invest in equipment that can convert your swarf into briquettes. Other equipment may be used to help remove the coolant from the swarf so that it can be recycled or reused as well.

Extra Credit: What is Swarf Milling?

The term "Swarf Milling" refers to a type of 5-Axis milling toolpath. With Swarf Milling, the tool is positioned so milling is being done by keeping the tool so its side is always tangent to the surface being machined. Another term for Swarf Milling is Flank Milling.

Frequently Asked Questions (FAQs)

Why is it called swarf?

From Middle English "swarf" meant "iron filings" or "rust".

Is swarf hazardous waste?

Stel swarf is a hazardous waste that is challenging to recycle due to its high content of heavy metals and cutting fluids. Today it is commonly landfilled.

What is the danger while handling metal swarf?

Metal swarf can have extremely sharp edges that can result in serious cuts or even loss of fingers. In addition swarf is often coated in coolant which is potential flammable or toxic.

How do you safely dispose of swarf?

Collect swarf into a container for recycling. Swarf should be dry. When handling wear long pants, close toed shoes, work gloves, and eye protection.

Can swarf be recycled?

Swarf is metal waste contaminated with oil, water, and other components of coolant. The waste is considered hazardous but it is also a resource which can be recycled.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.