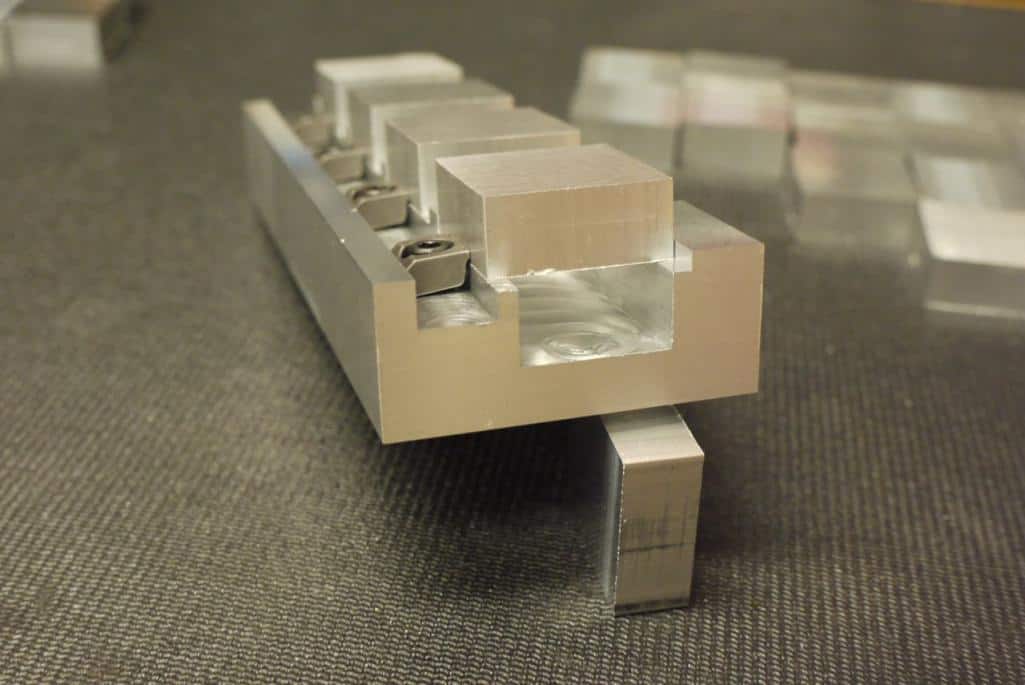

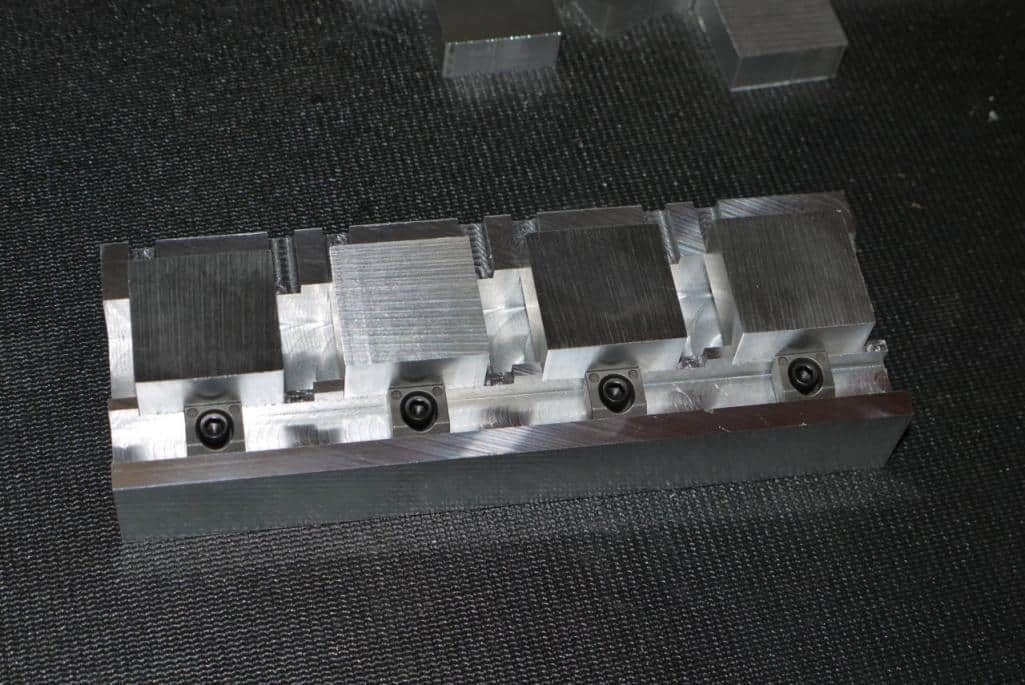

A significant aspect of sophisticated machine operations lies in the fixturing and workholding. Consequently, I remain alert when people share images of their fixtures. And who knows, he may be an unbeknownst poet! Have a look at this neat, straightforward fixture from Travis on CNCZone:

It's kind of like 4 little vises, and you could stick this fixture into a machinist vise (or 2) as a pallet. Pallets are great because you can be setting up parts on alternate pallets while the machine runs. This particular fixture is made of aluminum, which, as the CNCZone thread commenters say, won't last too long. Steel would be better, but more trouble if you don't need a lot of parts.

You won't save time and money every time making a specialized fixture. In fact, we added a special Fixture Calculator to our G-Wizard Estimator to help you figure out when it makes sense. But there are some kinds of fixture tooling that are generic, and could be used in a variety of jobs once made up. This is that kind of fixture, so it might be worth it to have a few of them hanging around.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.