Restoring the Usefulness of My Mini Band Saw With a New Table

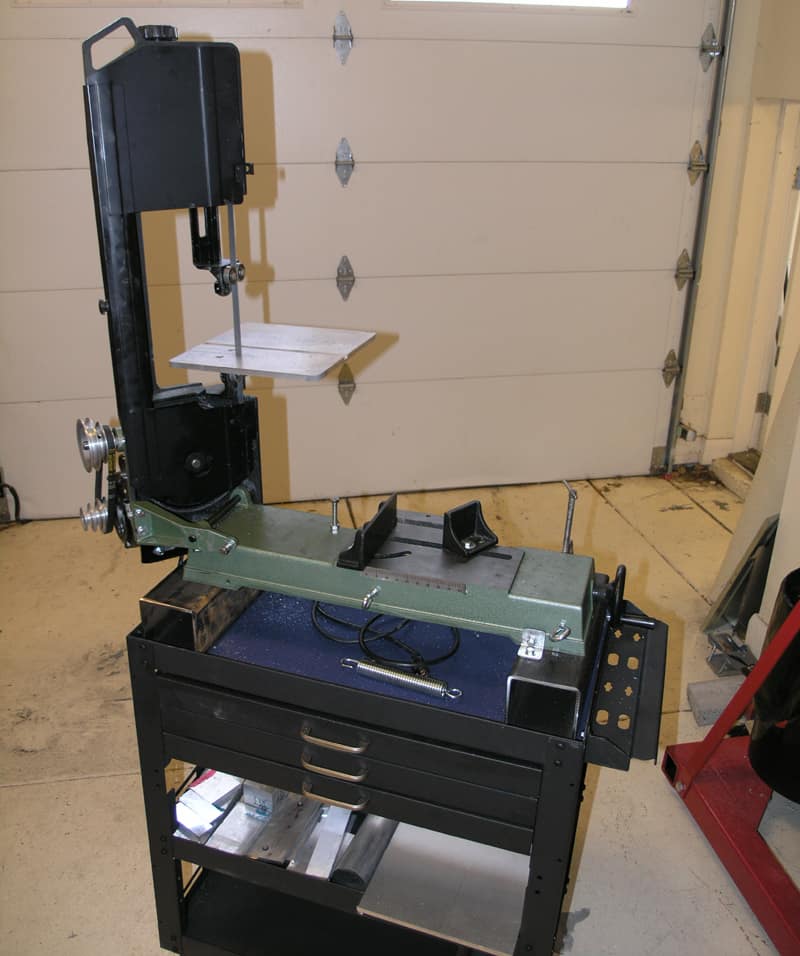

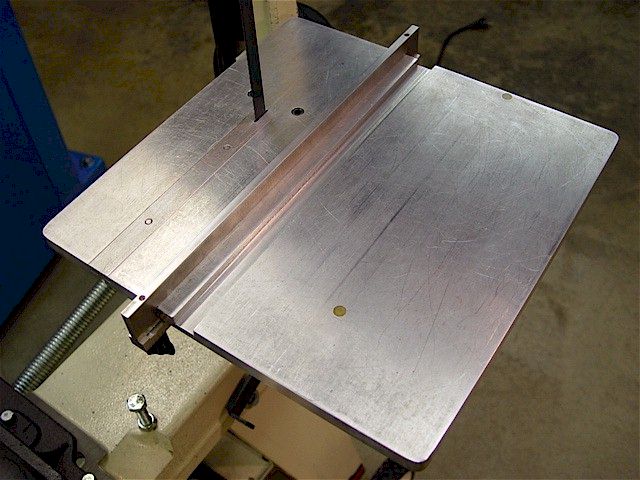

I made a quick afternoon's work making a new table for my mini-bandsaw and mounting it on a cart I use to keep small pieces of work stock:

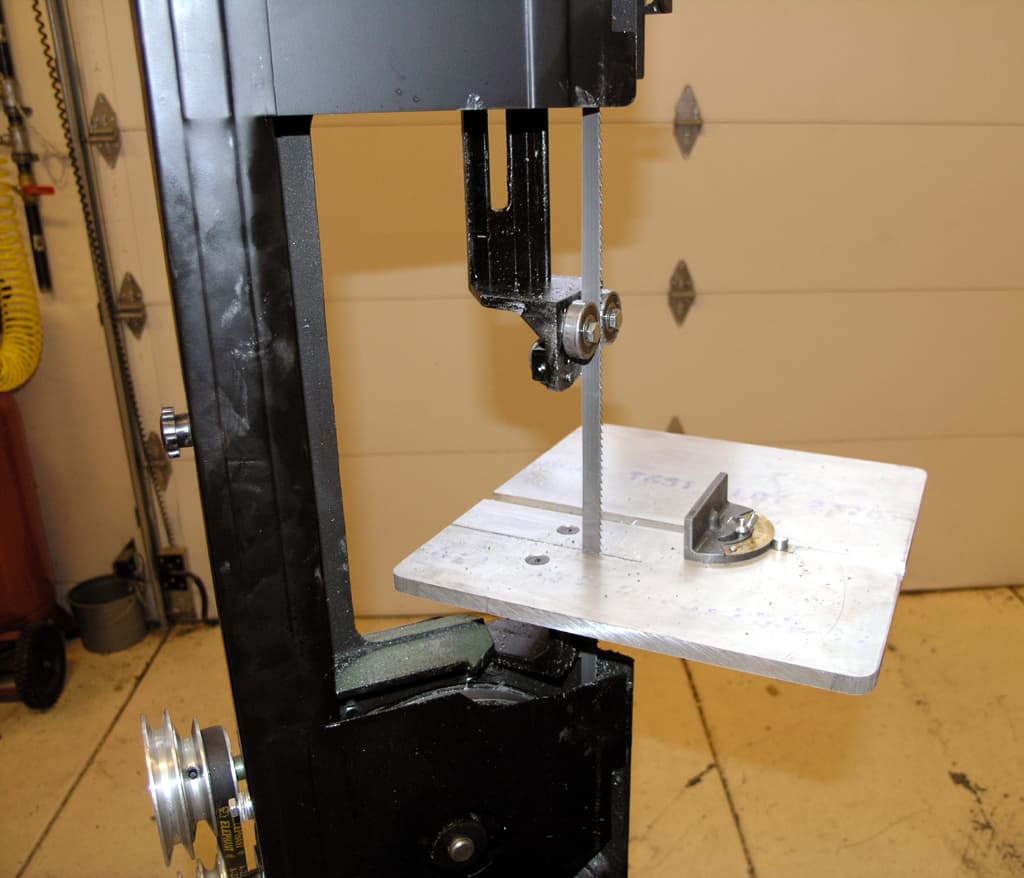

Since getting my DeWalt Multicutter, the bandsaw has been moldering in a corner. It simply is not nearly as nice a tool for cutting long pieces of stock to size. I'd been admiring some other people's bandsaw improvements for a while, and one day I spied a piece of aluminum that I decided would make an ideal table. By building a nice table for the saw, I figured I could leave it in the upright position and use it for fine trimming work that isn't possible with a big cutoff saw. Here's a better view of the table:

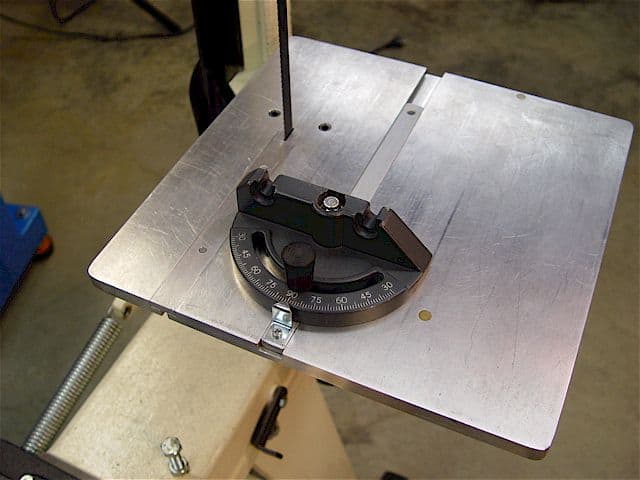

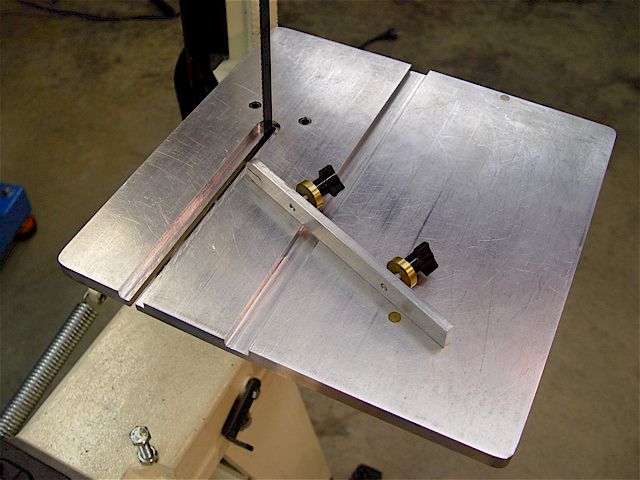

Just as with my 12" Disc Sander project, I made the table so I could use the same tooling. In other words, the tooling slot the mitre rides in is the same distance from the cutting area on my HF Tool Grinder, Disc Sander, and now the bandsaw.

The little cart was $79 on sale and with free shipping from Northern Tool. It's a nice cart for small stock and a far sturdier platform for the bandsaw than the rickety sheet metal legs that come with it.

I paid a grand total of $29 on eBay to buy that saw used, and that included shipping. I've definitely gotten my money's worth out of it by now. Until now, the only thing I'd done to it was to clean it up (it was filthy and well used when it arrived), adjust the blade tracking and cutting tension a couple of times, and buy a nice Starret bimetal blade for it. No sooner did I get the table finished than I was using it to trim stock for another project. I predict it'll be handy to have the little guy running again. If the chop saw goes on the fritz, I can pull the table off with two bolts and keep right on trucking until I get it fixed.

The Original Inspirations

As with so many of my projects, I didn't think of either of these. The ideas came from other kind souls out on the Internet. Below are the photos and notes I held on to for about 3 years before I finally got 'round to it.

One of those obvious, "Why didn't I think of that?" projects is to adapt a rolling tool cart to hold my HF bandsaw. The stand they come with is junk anyway.

Given how hard it is to come by storage in a shop, I am tempted to mount every machine I can on top of a rolling tool chest with lots of drawers or a rolling cart like this one. Note: this concept was the genesis of several projects, including my welding table.

Dickeybird's HF saw on an HF cart...

I don't use my bandsaw for cut off much after purchasing a DeWalt Multicutter, so I need to make a table for it and just leave it upright. I could use a table for fine work:

I would add a slot for tooling such as a mitre block. Probably would match it to the slotting that's on my Harbor Freight Tool Grinder which also matches my 12" Disc Sander...

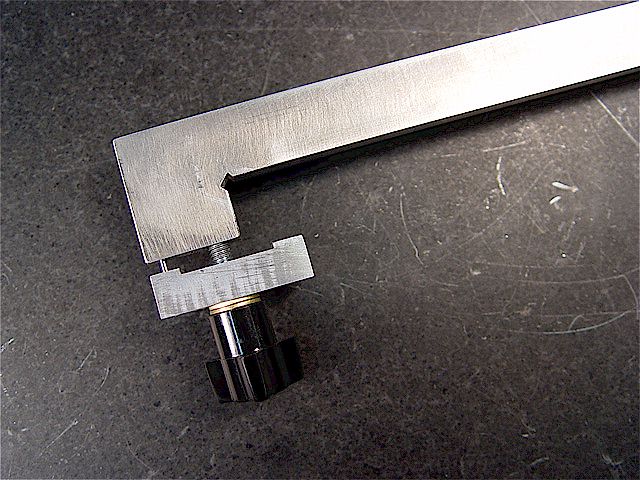

Micro Machine Shop has a beautiful table. Slot cover attaches ingeniously from below. Great site by the way!

He also made a nice rip fence. I need to make one of these some day!

More Bandsaw Mods

Tricks for the Vise

The vises on these bandsaws are definitely a weak link. With shorter stock, the floppy vise just won't hold. There are all manner of tricks to help out, and here are several:

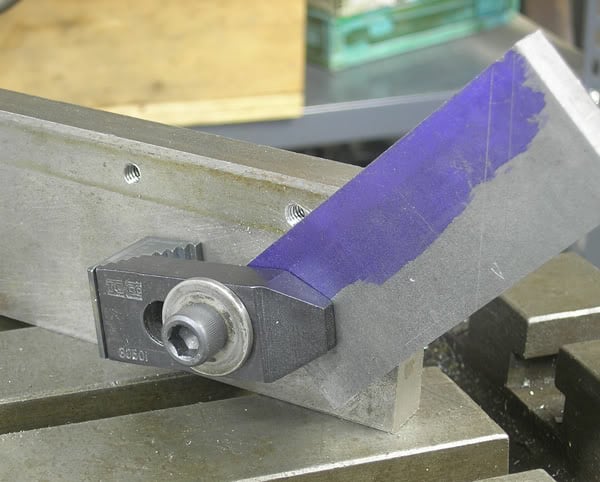

Two key vise improvements for shorter stock: The table clamp and the screw on the LHS of the jaw...

McGyver's Clever little vise sled is a complete tooling system for the little bandsaw vise...

Makes short work out of slicing a little bit off a little bit!

Flip it up and you have a bandsaw fixture plate with many more uses!

I like Bodysnatcher's Speed Handle for his bandsaw vise!

Here's a neat idea from Gary Hart. Bolt a little chunk of bent iron to a small vise...

Now you can insert it into the bandsaw vise for cutting real small pieces...

Another from Gary: Weld an extension on the outbound piece from the vise and you now have a convenient clamping platform...

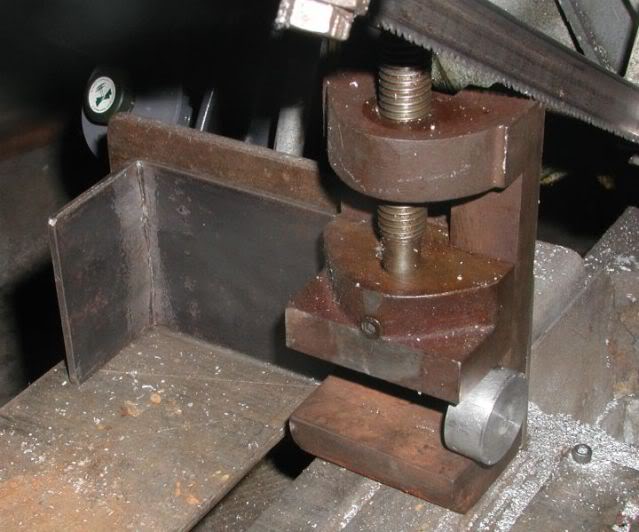

John Stevenson's Bandsaw Jack Screw mod for holding small pieces of stock...

Coolant

People put misters on these little saws, but I like Evan's elegant and inexpensive little solution better:

Evan's clever approach to coolant. A drop oiler. If you tilt the saw up, the drip stops.

Ultimate CNC Mini Band Saw Project

I'm fascinated by all things "automatic". I don't know why, as I'm not running a manufacturing facility, but somehow these things just attract me. Here is a marvelous air-powered bar feeder for a small bandsaw that I found on the Chaski Boards:

The overall feeder

Feeder clamps. Cylinder on right is fixed. The one on left is on a sliding bed. To feed, release the right, clamp the left, and slide forward. Clamp the right, release the left, and slide back. That's one cycle.

The air cylinders are actuated by SMC air valves, and the overall automation is controlled by an Allen-Bradley Micrologix 1000 PLC.

Is that cool, or what? This has to be the ultimate mini-bandsaw mod!

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.