Lollipop Cutters, also known as Undercutting End Mills, can be very useful for certain situations. But they also have their pitfalls and limitations. For example, the shank is smaller than the ball diameter, so they're more subject to tool deflection than you might expect. In an undercutting situation, excess tool deflection can get one into trouble in a hurry.

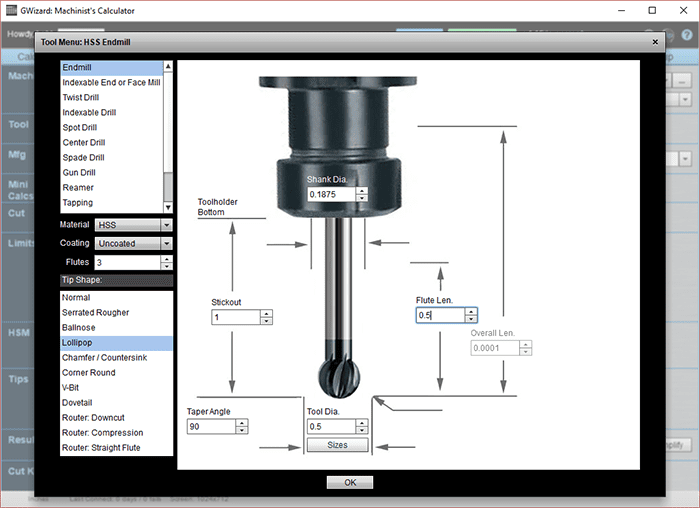

Here's what a the Lollipop Cutter looks like:

That's a shot from G-Wizard Calculator's Geometry menu, and you can clearly see why they're called :"Lollipop Cutters". The term "Undercutting End MIll" comes about because these cutters can actually reach under a shelf to remove a little more material, a process which is called "Undercutting."

Lollipop Cutter / Undercutting End Mill Feeds and Speeds

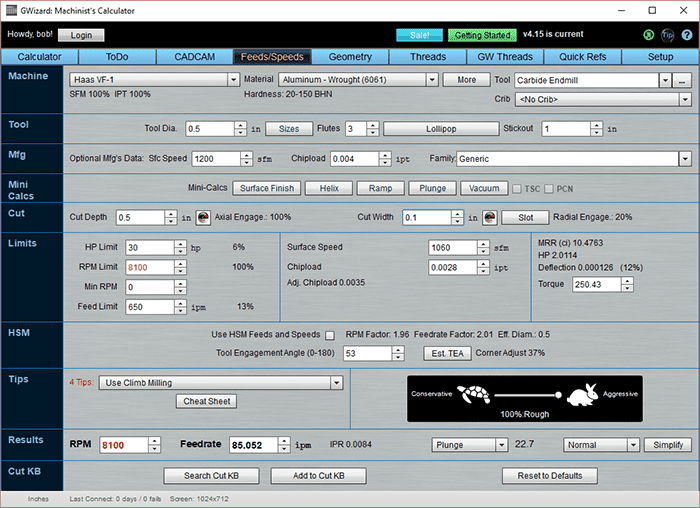

G-Wizard Calculator makes it easy to get Feeds and Speeds for Lollipop Cutters. First, realize that Lollipops are a special tip type for End Mills. So, proceed as if selecting an End Mill:

The screen shot has us set up to cut 6061 Aluminum with a 1/2" 3 flute carbide end mill. Click the "Geometry" button and switch to a Lollipop. While you're at it, enter the Lollipop's dimensions, and be sure you get the shank diameter in there:

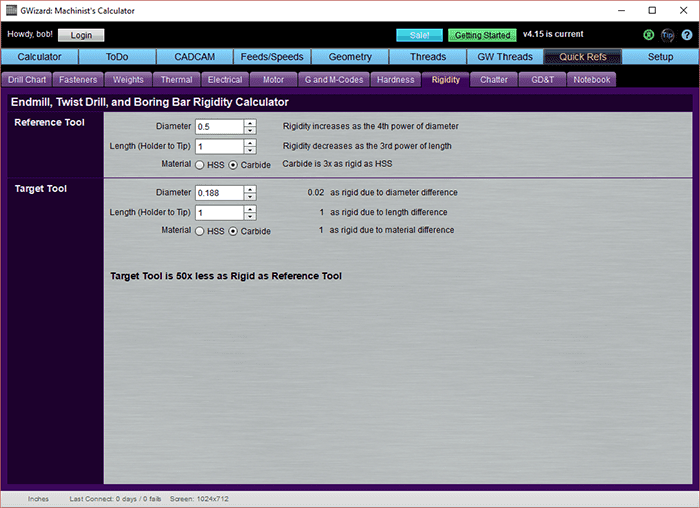

This Harvey Tool Undercutting End Mill is a 1/2" diameter, but the shank is only 3/16". As soon as we hit "OK" on that geometry window, we can see there are Tool Deflection issues. Let's refer to G-Wizard's Rigidity Calculator to understand what's going on:

All other things being equal, a 3/16" shank is 50x LESS rigid than a 1/2" shank. 50 times has a HUGE impact on tool deflection, and that's why if you're going to use Lollipop cutters, you want to make sure you're using G-Wizard Calculator or something similar with support for these cutters.

Instead of a Cut Width (Stepover) of 0.5", which is a full slot, if we click on the "Cut Width" title, G-Wizard will tell us the maximum Cut Width we can run without a Tool Deflection warning. It turns out we need to dial back to 0.066".

Lollipop cutters are best used gently and under watchful eyes lest deflection severely limit their Tool Life.

BTW, a Woodruff Cutter is also commonly used for undercuts.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.