Many individuals have inquired as to why, in G-Wizard, the chip loads for HSS are higher than Carbide when all other variables are consistent. After all, isn't it assumed that Carbide is always speedier when it comes to speeds and feeds?

Well not always. Carbide is much stiffer than HSS, and this can be helpful to reduce chatter or with longer reaches. This is why we can use longer boring bars and endmills if they're solid carbide. However, if vibration is not a problem, this stiffness is offset by Carbide being more brittle than HSS. For that reason, it can't take as big a chip load without chipping, all other things being equal.

This is more than made up for in many situation's by Carbides ability to run at much higher surface speeds. Even with a lower chip load, we can run higher feedrates, provided we can maintain the spindle speeds needed for those feedrates.

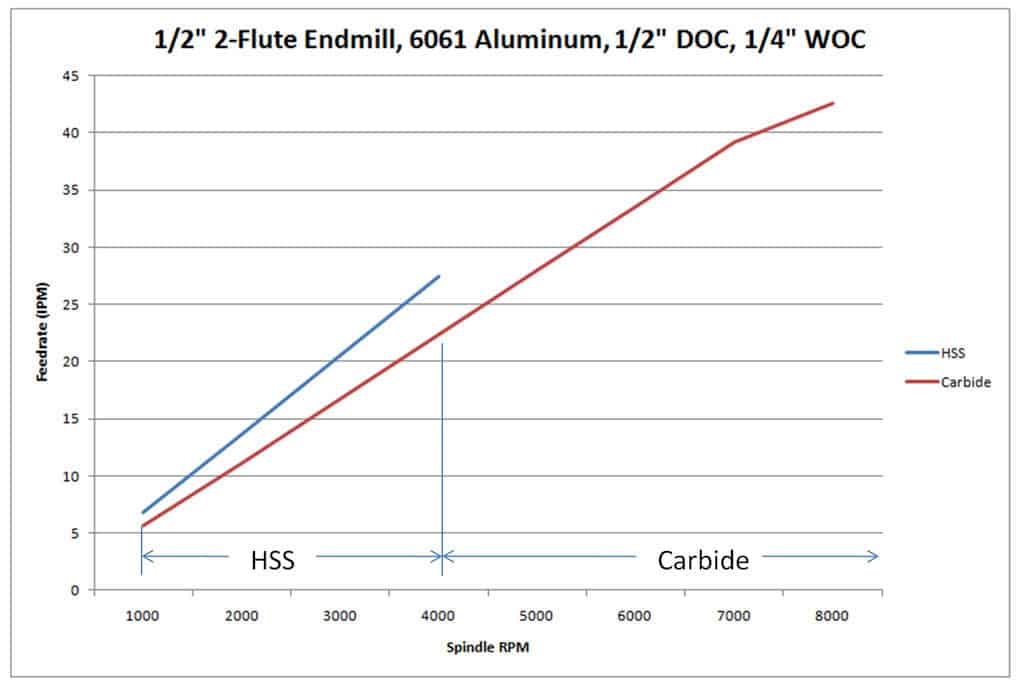

I thought it would be interesting to compile the trade off data from G-Wizard into a chart so you can see graphically where each one excels:

Regions where HSS vs Carbide has a better material removal rate due to a higher feedrate...

As you can see, if your spindle is only capable of running at 4000 rpm or less, HSS has a higher material removal rate, all other things being equal. This is because the higher chip load of HSS allows a higher feedrate. But, HSS for this 1/2" endmill case, maxes out at a 4000 rpm recommended spindle speed. If you can go faster than that you can beat the HSS material removal rate. In fact, there is a "dead zone" from 4000 to about 5000 rpm where the carbide is catching up to the HSS's early lead, so it would be more fair to say 5000 rpm is the dividing line for this scenario.

This is not to say that there would never be an advantage below 5000 rpm to carbide. Remember, it is more rigid than HSS. If you're having a lot of trouble with chatter or deflection, perhaps because you have a long reach tool, carbide may help quite a bit. This is also 6061 aluminum. Even mild steel is going to shift the tradeoff to much lower rpms because HSS can only be run much more slowly in harder materials.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.