Sheet Metal Folding

The demand to perform sheet metal folding arises relatively frequently in many workshops. This article explores the variety of machinery and tools available that simplify this process, even when done almost on a production scale.

Hydraulic Press Brake / Shopmade CNC Press Brake

Press brakes are cool machines for bending sheet metal. The CNC variety have what is called a “back gage”. You insert the sheet metal through the opening until the back of the workpiece hits the “back” gage and step on the pedal to do the bend.

You can set up a variety of tooling in the opening, and a skilled operator can walk the workpiece through each station of tooling to make a finished part:

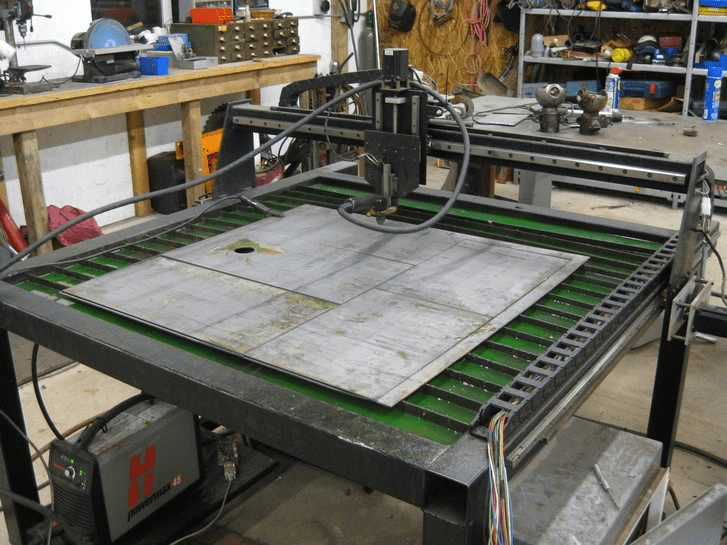

Meanwhile, there’s a guy over on CNCZone who has done a post showing how he built a CNC press brake from scratch. Very cool project! Here are a couple videos and pix:

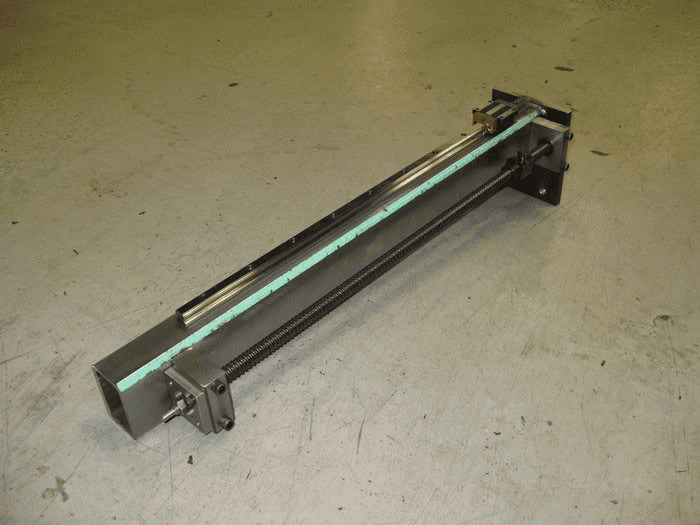

Demo of the back gage showing how it can move in 2 axes…

Bending some test parts…

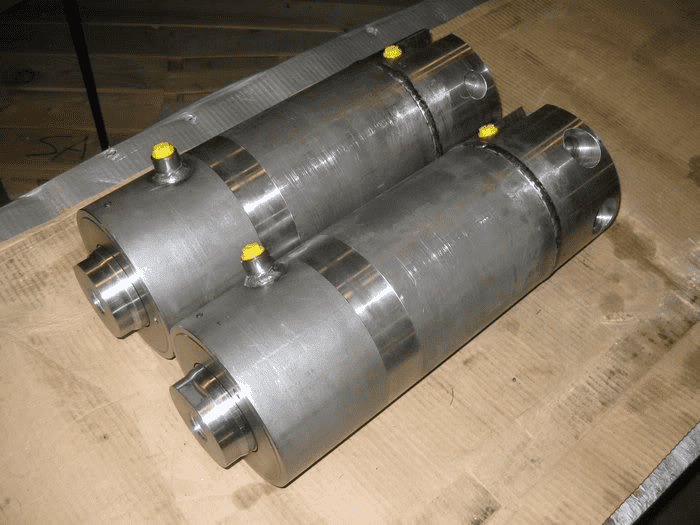

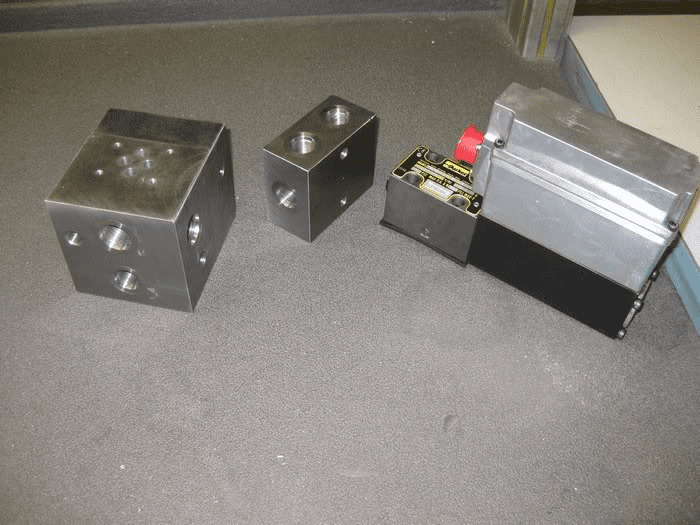

Cylinder raw materials, and finished cylinders (this fellow does this kind of thing for a living, BTW)…

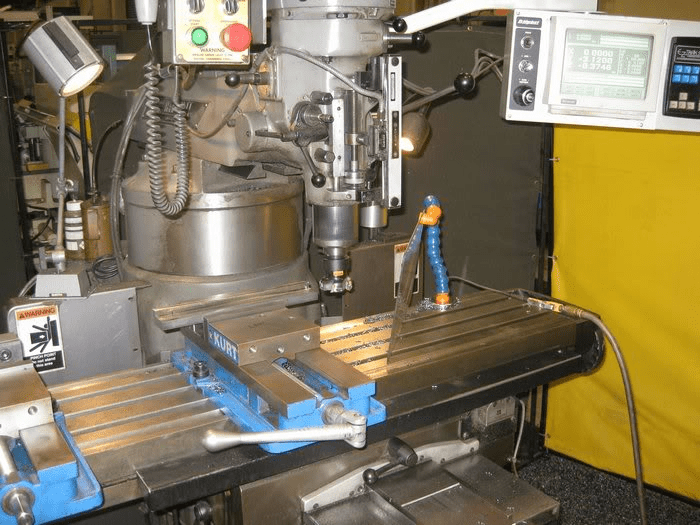

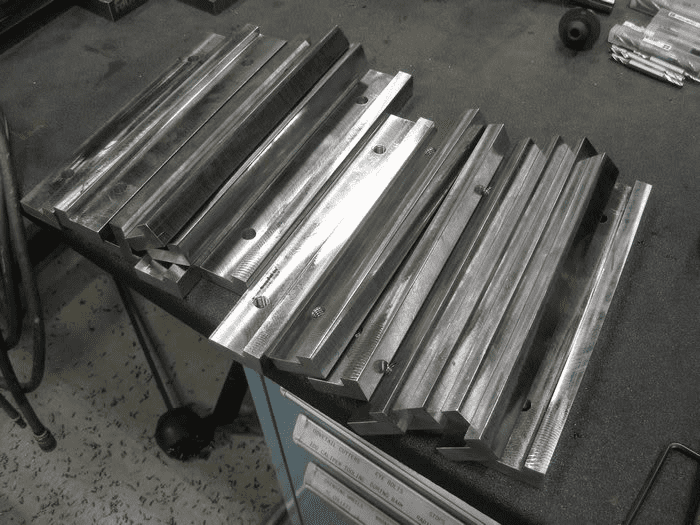

Machining the upper and lower die holders…

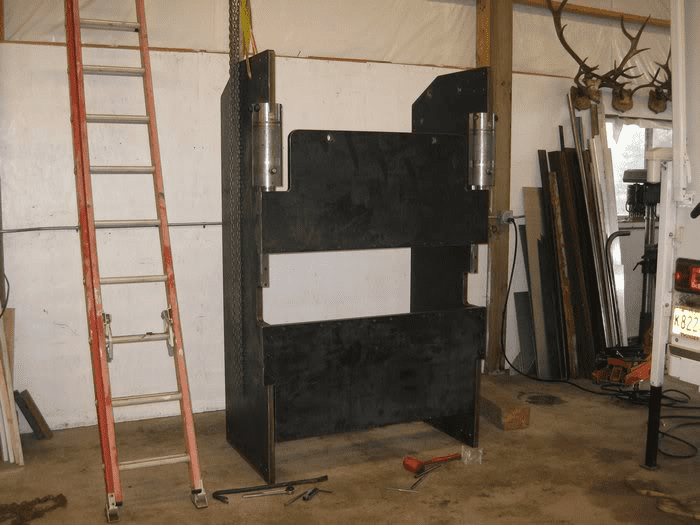

Plate was flame cut (2600lbs worth!). Ram is guided by some large two truck linear bearings…

He built a plasma table too and used it to cut the pieces for the hydraulic tank…

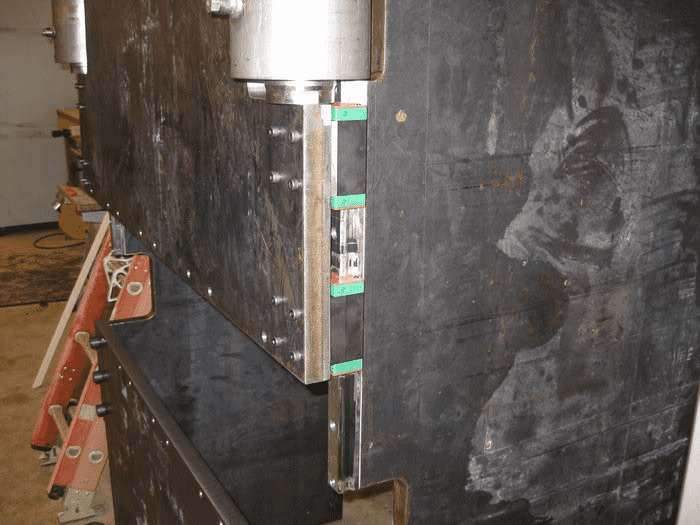

Back gage and hydraulic manifolding…

Press Brake Attachments

If that Shopmade CNC Press Brake project looks a little daunting, fear not. There are much easier solutions to your sheet metal folding and bending needs, albeit they are nowhere near as slick and can't compete for production quantities.

If you've got a hydraulic press in the shop as many do, you might consider building a press brake attachment for your press. This is basically a little gizmo that holds your press break dies and lets the hydraulic press do the work.

Here is a design study I did in Rhino. My press will accomodate a 15" by 31.5" opening. This brake is designed for 24" punches and dies.

This is a work in progress, and will probably change significantly before it gets built. There are some open questions. For example, I'm showing 1" shafting for the linear bearing system. It might be better to go up to 1 1/4" or even more. I'm showing a 5/8" deep tooling slot, but apparently 13/16" is the industry standard for press brake tooling holders.

I'm planning some pretty basic specifications:

24" wide tooling held via set screws in a standard 1/2" by 13/16" deep slot

Back gauge features:

- Raise and lower the gage bar

- Slide back to the right bending depth

- Fingers on the gage bar are adjustable

Inspiration

As usual, I have been canvasing the various online resources to get ideas.

Below is a collection of photos and links that are serving as inspiration.

Talented German amateur's brake with rubber die:

Gundog's very nice brake and press:

UHMW die prevents marring of work...

PM Thread on Press Brake Attachments:

Note the massive guide system on the sides...

Other Pictures:

Nice brake from the Metal Illness Board:

Links

American Press Brake Punches & Dies: Great information on the basic punches and dies for a press brake. Note the standard 1/2" by 5/8" tab that is used. I will build that into my design so I can run standard tooling that I find out on eBay and other places.

Tooling Notes and Operating Tips: A nice thread on WeldingWeb.com on press brakes.

4-way Die and Holder Dimensions: A 4-way die would be really slick.

ShopOutfitters: The nicest ready made press brake attachment I have found.

Midwest Press Brake: More good reference data from a commercial supplier

Press Brake Tooling & Press Brake Dies

There is a huge variety of tooling and dies available for press brakes. It's built to one of a few standards:

- American Precision Style Press Brake Tooling

- European Precision Style Press Brake Tooling

- American Planed Press Brake Tooling

- Wila Trumpf Style Press Brake Tooling

- Bevel Tang Style Press Brake Tooling

Punches and Dies refer to two types of tooling. The punch is typically the male tool that press the sheet metal into the die or female tool.

There are basically three types of bending.

Coining

The term comes from making coins. Basically, high tonnage forces compress the metal to conform to the image on the die and thus coins are made. With a press brake, "coining" means using enough tonnage to conform the sheet metal to the exact shape of the punch and die.

Within coining, the tonnage is sufficient to imprint the metal, which usually just means it is made thinner when squeezed between punch and die.

Bottom Bending

Bottom Bending or "bottoming" can look almost the same as coining, but less force is used so there is no thinning of the material.

Because there is less force used and no imprinting, the material can springback from the bend. So typically, bends are made to a more acute angle to compensate for the springback when bottoming.

Air Bending

With this method, there is even less contact. In fact, there are three points of contact:

- Tip of the punch

- Two shoulder contact points of the die

The exact angle of the bend is therefore a function of how far the punch tip descends relative to the two shoulder contact points.

Box and Pan Brakes (aka Finger Brakes)

The traditional solution for bending sheet metal in shops has been a box and pan brake or finger brake. There are plans readily available to make nice ones such as this:

This bending brake is sublimely finished...

Plans for it are available from the Village Press book, “Metalworking, Book Two, The Best of Projects in Metal.”

Magnabend

A very slick step up from a traditional finger brake is the Magnabend.

Here's a great video that introduces the Magnabend:

MagnaBrake Magnetic Sheet Metal Brake

It's pretty easy to see from the video why one of these brakes would be a lot more useful than a conventional sheet metal brake. The interesting thing is it doesn't look that hard to build one for your shop. The inventor has a site with quite a few details. I'm wondering how hard it would be to apply some simple CNC to one in the form of a motorized bending gage as well as motorizing the bending action.

Links

Practical Machinest Thread on Electromagnetic Brakes

EIS Online Nomex Insulating Paper: Extra insulation for the electromagnet

EIS Magnet Wire: For winding the electromagnet's coil.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.