Have you thought about using a drag knife with your CNC Router?

Drag Knifes are really handy for cutting soft materials like vinyl, cardboard, mat board, foam, wood veneer, leather, and many others. With flat sheets, you might use a drag knife to create some custom packaging for some product, for example, or at least to prototype the packaging. There are so many possibilities:

- Use it for delicate veneer inlay work. Cut the thin veneer material with a drag knife and then glue it into pockets made via cnc router.

- Use it to cut vinyl for signs and decals. Sign vinyl is particularly easy to cut, so you can use a smaller Vinyl Cutting Drag Knife to cut it.

- Use it to cut felt to line your jewelry and other kinds of boxes.

- Use it to make a stencil for spray painting out of thing plastic.

- Use it cut leather when making leather goods.

- Use it to cut carbon fiber.

The possibilities are endless.

DIY Drag Knife

Commercial drag knives are readily available, but can be a bit expensive for the hobbyist. I recently came across a great CNCZone post for this drag knife:

As you can see it uses a utility knife blade. Since we are using consumable blades, we want some that are easily obtainable when its time to replace a dull blade.

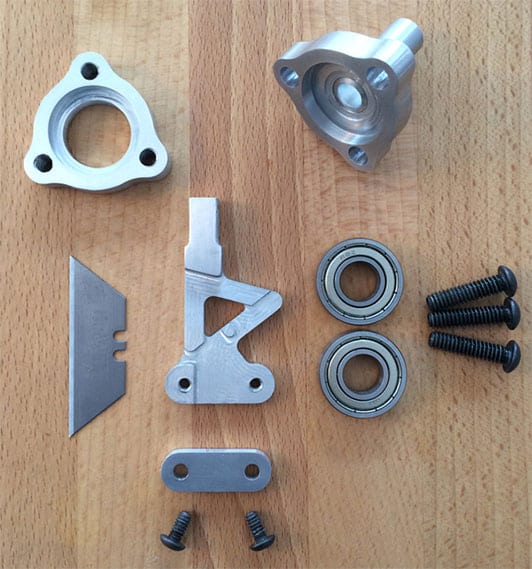

Here the drag knife is broken down into component parts:

Drag Knife components...

As you can see, the drag knife is pretty simple and would be pretty easy to build. The main thing in designing drag knives is to hold the blade so it has a vertical dull edge that is fairly close to the axis of the shaft but still off axis enough to have a little castering effect. There are fancier drag knives available that even put a 4th axis servo to control knife direction, but you can do a lot with a self-steering drag knife. Sometimes the simpler solutions are best.

We'll close with a nice YouTube video of the project:

Note his use of WD-40 when cutting aluminum. Good idea!

Programming and Using Your CNC Router Drag Knife

Tip: Check our library for free DXF files that you can cut out with a drag knife.

First, since you'll be cutting thin material, you need to make sure you have a perfectly flat surface that is aligned properly with your CNC Router. Your spoilboard must be perfectly smooth and flat. To achieve this, attach a temporary spoilboard to cover any fastener holes or T-track slots. Then, run a fly-cutting pass to make it dead flat relative to your cnc router travels.

Programming one of these drag knives may require you to perform what's known as a "corner action". In order to make a tight corner, you want to raise the blade up so the tip is barely touching the material-just enough so the material can barely grip it as it turns in the bearings. Now program the knife to move in a small circle around the tip to re-position it in the direction you want to move. Drop back down to cut depth and you're ready to head out.

VCarve Pro has a special fillet for Drag Knives that will add this corner action automatically.

If you're willing to radius all the corners, there's no need for the special corner action moves. Without corner actions, most any CAM software will give you a decent result with a Drag Knife. Just use an engraving style toolpath that follows a line in your drawing.

Donek Drag Knives

No time to make a drag knife?

No worries, they're available commercially. The Donek Tools drag knife is probably the best known brand.

The video demo shows some pretty amazingly sharp cuts being made at high speeds because the Donek tools drag knife orients itself. It takes ordinary utility knife blades and comes in 2 sizes.

Donek Tools founder Sean Martin invented the Donek Drag Knife to cut graphics for the custom snow boards he was making on his Shopbot CNC Router. They're sold commercially as the Donek Tools Drag Knife.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.