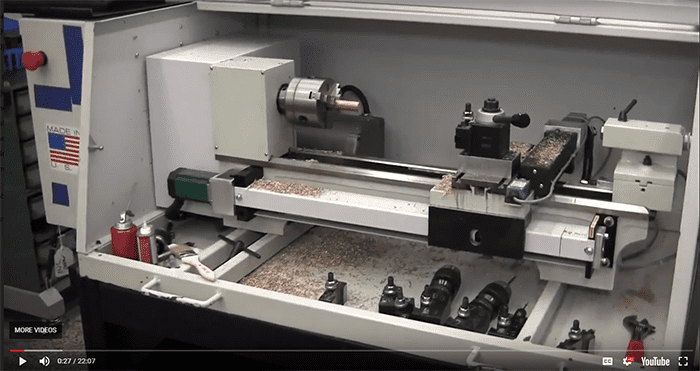

Take an inexpensive CNC lathe from eBay for $1200. Inexpensive because the electronics don't work. Add a powerful Centroid Acorn Controller (also not too expensive) and you've got the slick little lathe that Centroid uses to test their controls:

Just the basics, but they're all there!

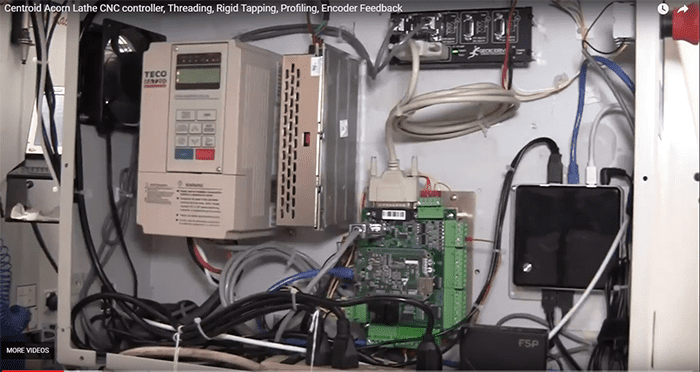

Inside the control cabinet...

Inside the control cabinet things are clean and simple. You can see the VFD for the spindle at the top left. There's a Gecko G540 (black box top right) driving the steppers. The parallel cables makes the connection from the Acorn Controller (green board bottom center) super easy. And there's a PC inside the little black box running the Acorn software.

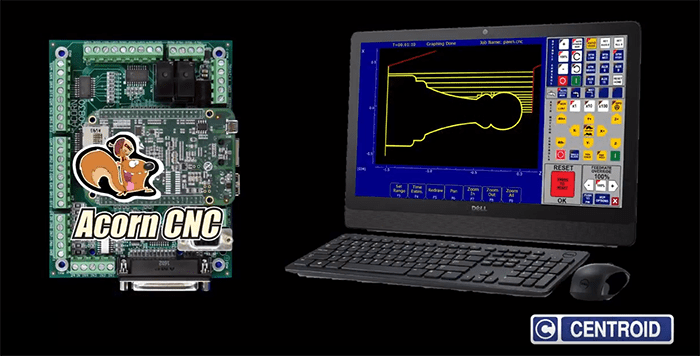

Speaking of which, here's a shot:

Centroid has been around a long time and has a good reputation for their controls, but the Acorn is newer. I had several folks ask me about it when I ran the CNC Controller Survey recently, but I hadn't really dug into one at all.

I got the information for this article when Marty Escarcega, one of Centroid's forum moderators, contacted me about giving some CNCCookbook information out to their audience. I'm always happy to share the content on our website provided there's proper attribution, so the answer was, "Yes!", of course.

Marty included a slick video that tells the story of this nifty lathe:

Video about Centroid's Acorn controlled CNC lathe...

Lathes are great, BTW, and CNC Lathes are even better. If this machine had been available to me off the shelf at the time, I might very well have one today. The price is right for a home shop. Also, its size is perfect for my shop which is a touch cramped. Plus I like the toolroom approach with decent distance between centers and room for a tailstock.

I love PathPilot on my Tormach Slant Bed lathe, but this control has some pretty sweet features too:

- Conversational Programming

- G71 reveals a powerful dialect of G-Code, Fanuc compatible. I've been telling anyone that will listen to make their controls Fanuc compatible for a long time, but most don't listen, LOL.

- Accurate repeatable homing via encoders connected to the home switches.

There's probably a lot more, but that's what I took away from the video. It was a great intro, and I'm hoping Centroid will send me an Acorn to play with. I've got several machines here I'd like to hook it up to, mostly my CNC Router. Yup, the Acorn is good for mills or lathes.

It's not really a fair comparison to put this little guy against Tormach's lathe. The Tormach is in a different class as it is bigger, heavier, and more rigid. Plus, it's got an awesome gang tooling and sweet 8 station turret as well.

If you're into DIY CNC Machines, have a look at the Acorn control. Hopefully I can provide even more insight in the not too distant future.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.