Deep pockets with tight radius corners are a real headache. Imagine a 2" deep pocket that needs 1/8" radius corners. The biggest endmill that can get in the is 1/4". But with a 2" deep pocket, you're facing an endmill with an 8:1 length to diameter ratio. It's going to want to deflect like crazy, so you'll have to go super slow to get it done. Plus, a smaller cutter is going to have to go slow everywhere else in the pocket. The bigger the pocket, the longer this will all take.

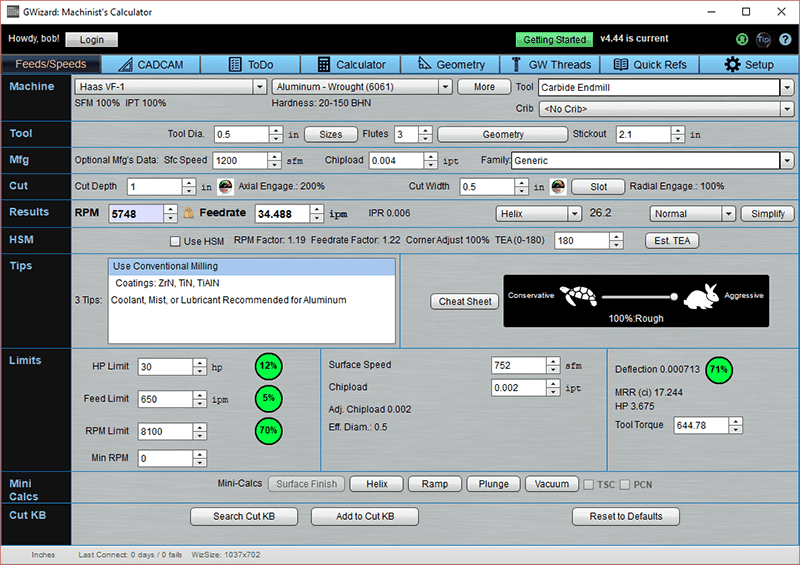

Consider how fast a 1/4" endmill has to go (using our G-Wizard software to find Feeds and Speeds) to get it done in 2 passes:

You didn't provide any text to be rephrased. Please provide the text you want rephrased.

We wind up having to use a tiny 0.0863" stepover to get the Deflection just barely (99%) within limits. MRR on this cut is only 0.8987 cubic inches per minute. That's slow going!

What if we could use a 1/2" endmill instead?

We can use full slotting if we want to for a whopping 17.244 cubic inches per minute and the deflection is no sweat. That's before we even optimize the cut to use an HSM toolpath like adaptive clearing or volumill to get even more.

Think of it, our MRR is about 19x faster. Now we're talking!

Just one little problem. We can't cut those 1/8" radius corners with that endmill. What to do, what to do?

First thing is to ask the customer or whoever designed the part if they really need 1/8" radius corners? Would a larger radius do? Because the part is a lot cheaper if it would.

But, assuming you must deliver those corners, it's time to have a look at a technique called "Corner Drilling".

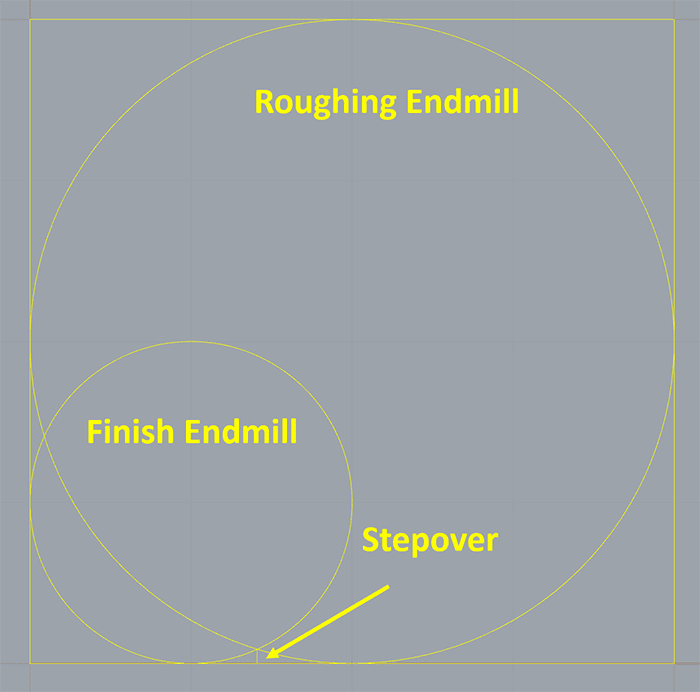

Here's a diagram to help you visualize the idea behind Corner Drilling:

You can see the small, finishing endmill sitting right in the corner of the pocket. A larger (2x the diameter) roughing endmill is sitting as close as it can get to the corner. And the short line segment marked "Stepover" is the amount of finishing allowance we want to leave for the small endmill.

The operation is going to work like this:

- Use a twist drill the diameter of the Finish Endmill (or the corner radius times 2) to drill a hole in the corner. Don't put the edge of the hole right on the pocket wall because you'll never it it to line up exactly right and look right. Rather, inset it diagonally away from the edge by and amount equal to the Stepover. We do this before roughing out the pocket so we're not drilling a partial hole, which can lead to problems. BTW, if the pocket is deeper than 5x the drill's diameter, you'll need to do some Peck Drilling.

- Now rough out the pocket with the larger roughing endmill.

- Finish using the smaller endmill that fits the corner and a finish allowance equal to the stepover.

For this ratio of cutter sizes (e.g. Rouger is 2x the Finisher), the Stepover is 0.0884 times the Finish Endmill's Diameter. That'd be 0.0221" for our example, which is less than our Deflection-limited Cut Width of above, so we're in fine shape.

You'll need a toolpath that does "corner peeling" to finish the corners because the material to be removed there is more than the Stepover, but most HSM paths will do a fine job with that. They often don't leave the best finish, so you might do 2 operations:

- Run Adaptive Clearing to get the whole finish outline to within the stepover allowance.

- Do a final finish pass with that Stepover from the perimeter of the pocket.

See how much faster that'll let you manage that nasty deep pocket?

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.