Stirling Engine Plans and Models

This page is largely links and pictures of model Stirling engines I've collected. Stirlings are fascinating "external" combustion engines that can be powered from a variety of heat sources. The "Low Temperature Differential" (LTD) Stirlings will run from the heat of the palm of your hand if they're made well enough, and by sitting atop a steaming mug of coffee if they're less efficient. Fascinating devices, no?

To build one that makes any power requires a fair amount of precision. I rate Stirlings as harder than steam engines, but MUCH easier than model turbines!

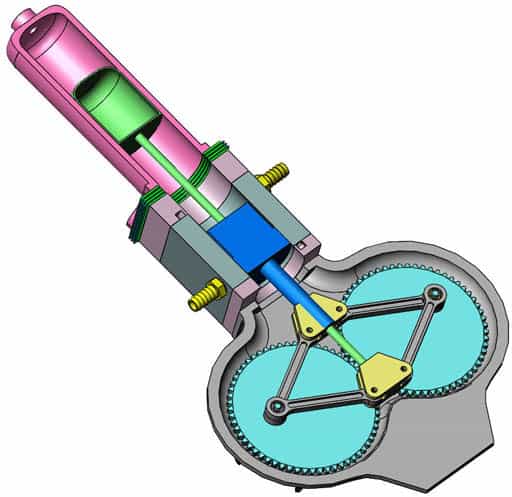

Here is a Rhombic driven Stirling:

I'm also interested in larger Stirling designs for the production of electricity from solar power. See my page on that for more.

My Stirling Engine Models

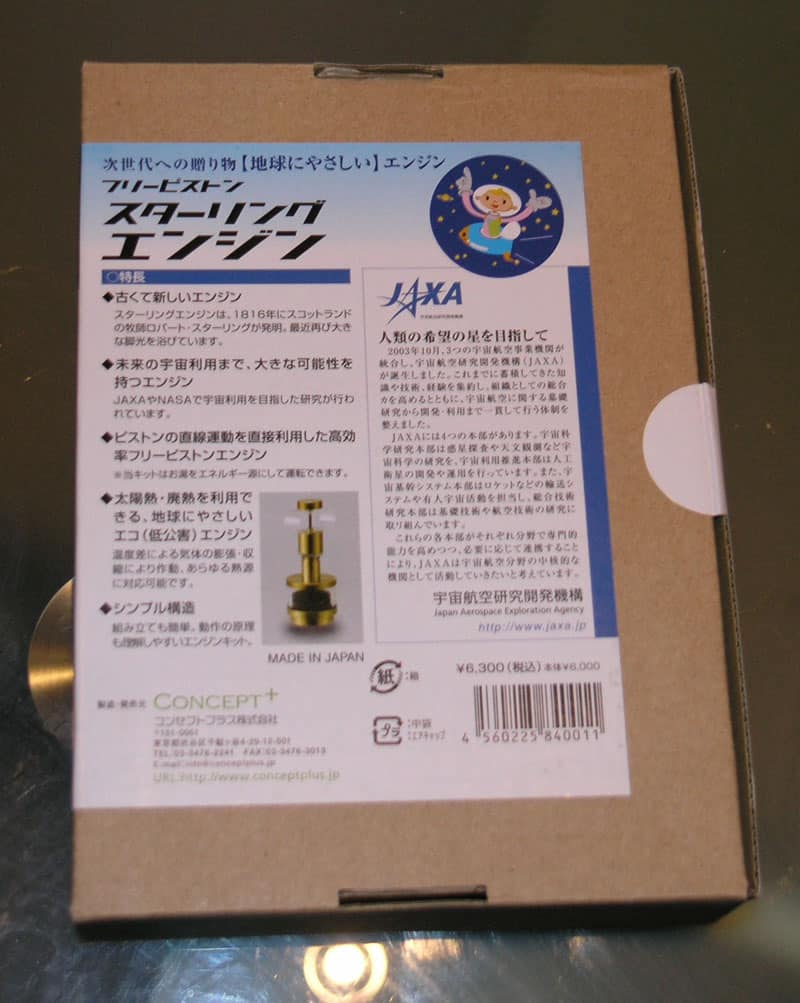

Jaxa Low Temperature Differential Free Piston Stirling

This was a kit that required no machine work, but it was fun anyway. It runs on a cup of coffee:

The box came straight from Japan via eBay…

Pretty simple set of parts. The celluloid plastic are “springs”…

It was running, but the camera stopped it. Click for a QuickTime movie…

If you want one, search for Free Piston Stirling on this eBay Store

Links on Stirling Engine Theory and Practice

Great Primer on How the Stirling Works

Nice spreadsheet walkthrough on how to design a Stirling engine

Excellent Schematic Overview of Various Stirling Configurations

Quirky Engines: Theory, various projects, and models you can order.

Wonderful Stirling Engine Animations

Great Collection of Stirling Articles Reprinted

Ivan's Practical Tips for Building a Stirling

Koichi Hirata's Model Stirling Pages: Theory, free plans, and a lot more

UK Stirling Engines Organization

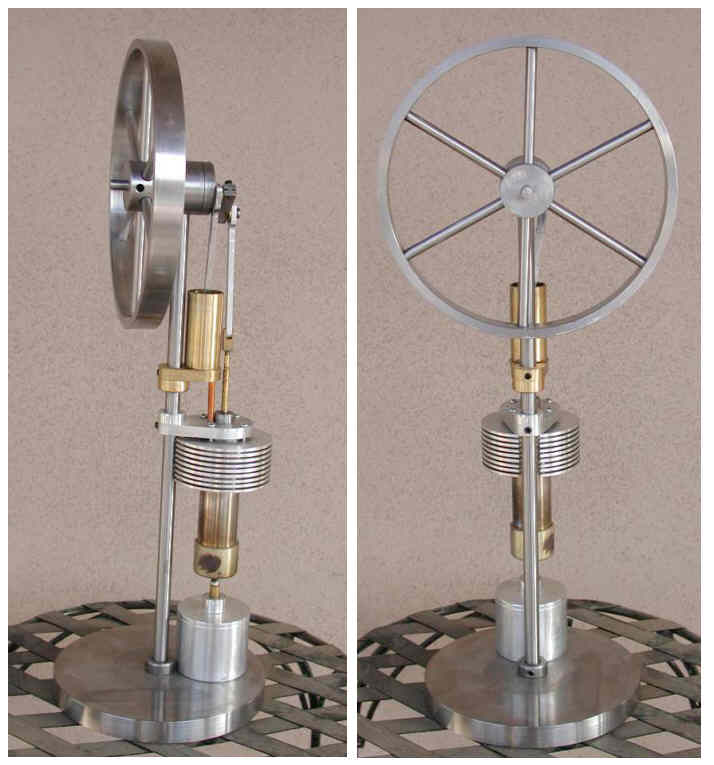

Typical layout for a model Stirling. This is the classic Kouhoupt model...

Links on More Specific Stirling Engine Models

Stirling-powered Robot Fish : Interesting Japanese project. Nice scale of Stirling.

Coffee Table Stirling Engines: Nice collection of photos.

Jon Bondy: Has built several model Stirlings, has a Stirling design program on the site, and keeps octopus and cuttlefish as pets. How do you go wrong with that?

Low Temperature Difference Stirling: Run a Stirling just by setting it on top of a steaming mug of coffee.

Steele Stirling Engine Plans: A 4-cylinder design capable of claimed 40 watts. It's about the size of a big model airplane engine.

A Tin Can Stirling: You can build a Stirling out of most anything, and need not even have machine tools.

Roy UK's Stirlings: Several to choose from made from simple materials.

Logic System Technology: Several interesting designs including a super low temperature differential Stirling that runs just from the heat of you palm.

Stirling South: Nicely made CNC Stirlings from some college professors. Here is the main Stirling page. The rest of the site is also quite fun!

Wonktoys: Another "no machine work" site.

Edward Bashauer: I love his Stirling Airplane Engine!

Alphonse Vassalo: Many finely crafted Stirling models including a 4-cylinder.

Bill Sondagh: Talented Netherlands builder has several nice models on display.

Daniel Lyonnet: Has built a number of Stirling models.

See-Saw Stirling: Not sure what one would use this for, but it would make for an interesting outdoor sculpture. A really novel Stirling design.

John Horne's Stirling Tractor: A museum quality Stirling-powered steam-style tractor model.

Barry Dunman: His "coffee table" Stirling is a delight.

John Hastings: Some nice LTD Stirling work!

Test Tube Stirling: Test Tube Stirlings may be the simplest way to play with a Stirling. This site has a nice one and a movie of it running.

Syl's Hobby Page: Lots of engines and other HSM projects.

Jos de Vink: Many beautiful engines styled in an old time Brass 17-1800's style.

Jan Ridder's Modelbouw: Many interesting engines on display, and he will send you plans too!

LTD Striling Plans: Plans for a relatively easy to build LTD.

Free Piston Stirling from Japan that'll run on a cup of coffee. Made by a company called JAXA. Here is a gallery of pix building one.

The Hermit's Machine Shop: A few Stirlings similar to Rudy Kouhoupt's including a Stirling fan.

Gold Stirling: Plans available, plus some gorgeous pictures of models.

Links to Other Stirling Engine Resources

Airpots: Marv Klotz says airpots/dashpots make great Stirling cylinders if you don't want to fuss with making one yourself. This company sells airpots ready to go.

Thoughts on Stirling Engine Models

- Marbles are 12.5mm in diameter (half an inch), and so a 14mm test tube works well for a Test Tube Stirling. Not sure about other sizes. Test tubes are abundant on eBay and cheap! Be sure to use heat resistant pyrex.

- Minimize aerodynamic losses. Pay close attention to gas velocity. Watch sharp bends, abrupt changes in cross section, anything the higher speed molecules will dislike. Move gas in parallel rather than series. Keep the bore big and the stroke small, probably around 10% of the bore. Think torque rather than speed.

- Minimize dead volume. Strive to move 100% of the gas from heated to cooled space.

- Use the correct compression ratio. Even better, forget the compression and use the correct expansion ration. They are the same number, but expansion better reflects the conversion of heat to kinetic energy. The ideal expansion ratio is the square root of the ratio of average absolute gas temperatures taken at the hottest and coolest points in the cycle. Since any gas not fully heated or cooled reduces this average, that's why heating and cooling as close to 100% of the gas is so important.

- Theoretically, you could double the pressure to get twice the work out of a Stirling. But twice the power means twice the heat energy in and out. If exchanger area remains constant, temperature losses will increase, and twice the power won't be obtained. Higher pressure also greatly increases flow losses resulting in further power declines. HIgher pressures also require more material to contain the pressure. That material might have been better utilized providing increased heat transfer area.

- Don't let the theoretical charm of the regenerator get in the way of the engine. To the extent the regenerator increases dead volume, or adds flow loss, it is the enemy of the engine.

- Stirling's 1815 design used the following ratios:

- length of displacer chamber L = 3 times its diameter.

- length of heater chamber = 2/3L

- length of cooler = 1/3L

- swept volume of displacer = 1.5 times swept volume of piston cylinder. This ratio is much larger for Low Temperature Differential Stirlings.

- length of displacer = 2/3L and stroke = 1/3L. Note that much smaller strokes lead to more efficient Stirlings. Other sources recommend a stroke that is 10% of the bore.

The purpose of making the heater chamber longer than the cooler was to maximize the temperature differential between the two. Use of thin wall tubing and making the chamber walls out of something that doesn't conduct heat so well (although it has to conduct the heat into the chamber, just not along the chamber longitudinaly) is also helpful.

Stirling Engine Model Gallery

Photos of Stirlings I particularly liked. These all came from sites in the links above.

John Horne's Stirling Tractor...

4-Cylinder Stirling by Alphonse Vassalo

Edward Bashauer's Stirling Airplane Engine

Alphonse Vassalo's Solar Stirling with an 18" Mirror

Alphonse Vassalo's "Backwards" Stirling has the hot section in the middle...

"Blazer" is a Duclos-designed Flame Licker by Roy Rice...

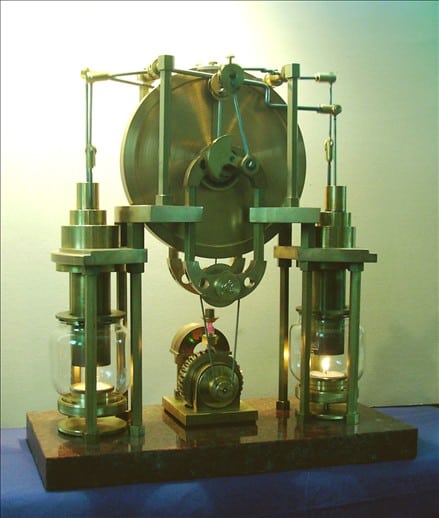

Barry Dunman's "coffee table" Stirling is a delight. It's amazing what can be done with test tubes and marbles!

Bill Sondagh of the Netherlands has a fine collection of Stirlings he has built...

Aquatap is a Ringbom Stirling by Roy Rice at Stirling South. The Ringbom requires no mechanical linkage between the two chambers.

Closeup of the gimbals and mechanisms on Barry Dunham's Test Tube Stirling. I still can't quite make out how the displacer end works...

Roy Rice's Rhombic driven test tube Stirling is way cool!

Detail of Rice's Rhombic drive...

Chuck Fellows built this very nice vertical Stirling...

An interesting and attractive Stirling that reuses an old OS model airplane motor...

Syl's Miser is an LTD with nice details...

"Beamer" is another nicely detailed engine by Syl...

A 3-Phase LTD Stirling built as a research project at UC Berkeley...

Classic Stirling Design...

Nice looking Stirling, apparently from a kit sold by Forrest Classics and made by Bohm. I like the styling...

Another ridiculously cool Bohm model! Looks like it took some waterjet or laser and CNC to make it. You gotta love the Steampunk + Raygun motif...

"Vickie" is my favorite Syl Stirling...

Jos de Vink's Beautiful "Kathedraal"

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.