Sometimes centralization is great-I've got all my tools in one gigantic rolling cabinet so I always know where they are. Except when I leave one laying where I used it last because I got distracted or forgot about it.

There's an alternate theory of organization, one that believes not only that centralization needs to be mobile, but that grouping things by task is also a good idea. For example, we wrote about Adam Savage's (he of the Mythbusters) idea that he wanted rolling carts for his tool where every tool is exposed and visible rather than giant tool cabinets where everything is hidden in drawers.

Kindly provide the text that needs to be rephrased.

Do you need an alternative to drawers full of jumbled tools?

This post is all about purpose-made stations. They gather everything needed to perform some specific task. Often, they're on wheels so they can be taken to where the work is needed and then rolled back out of the way once the job is done. Check out our photo essay of this approach to organization:

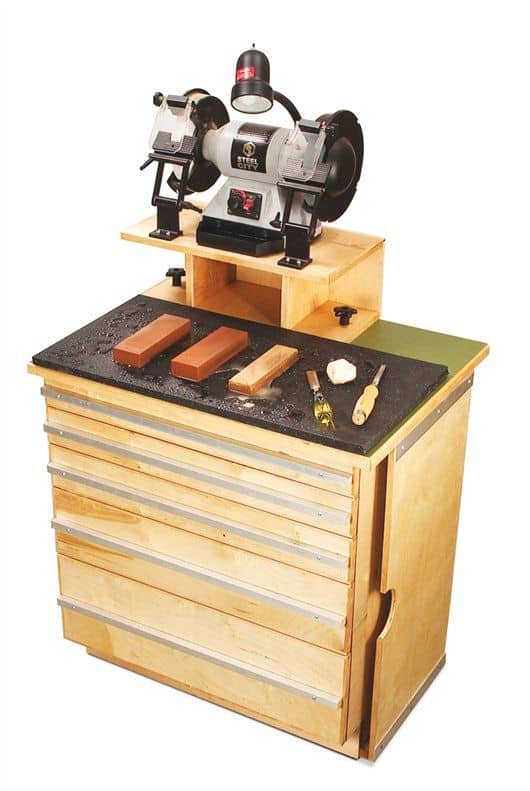

Polishing and sharpening station...

Grinder and Buffer station...

Compressor and air tool station...

Welding station...

Wiring station. Needs to tool storage for wiring and soldering on racks, perhaps along the back. Should also have storage for common electrical connectors and such...

Vise station: stuff that's handy when I work at the vise...

Toolholder Station. Everything I need to set up my machine for a job...

Shopvac station. It'd be nice to hide vac and cyclone inside the cabinet and put all manner of clean-up gear on the outside racks...

Small part assembly station. Use a Japan Rack to carry related tools to where they're needed.

Cleanup station. I'd make one with a handle on top and feet so it could be popped off the wall and taken to the site of a mess...

I could imagine many more specialized stations:

- Portable metrology and inspection station.

- Portable electronics bench with test equipment bolted down in racks and soldering and assembly gear

- Deburring station

- Paint and finishing prep with degreasing, masking, and everything else you need to prep a part for painting or powder coating

Here's another great article on Workshop Organization.

Tell us what kinds of specialized work stations you've used or would like to create for your own shop in the comments below.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.