With appologies to Waylon Jennings and his iconic, "Mommas, don't let your babies grow up to be cowboys," I present this bad day in the shop:

You haven't provided any text to rephrase, please include the text that needs rephrasing.

Fixing a broken T-Slot is darned near impossible...

Fixing a broken T-Slot is darned near impossible. Your best bet is to use it as an excuse to buy a fixture plate and just cover up that painful reminder.

Over torquing your T-Slot hardware can lead to this, but the most common way it happens is when the slot is being jacked instead of clamped.

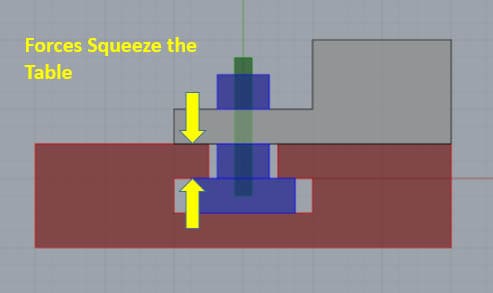

With a proper arrangement, the table is squeezed between whatever you're holding down and the T-Nut underneath:

Proper use of the T-Slot squeezes it...

Proper use of the T-Slot squeezes it, and it is quite strong in that configuration.

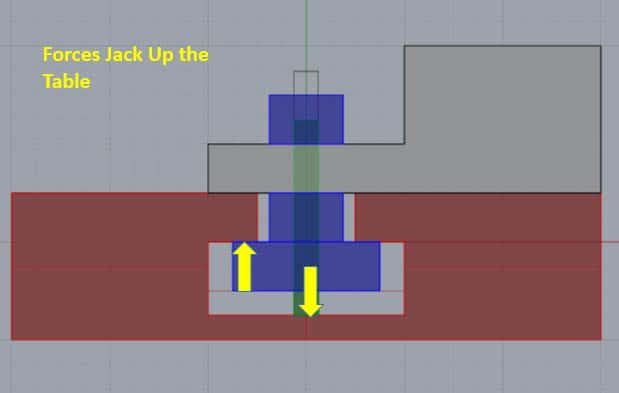

But, if the stud extends out the bottom of the T-Nut, the forces are unbalanced and pretty soon all the force goes to jacking the T-Nut up:

If the stud goes out the bottom of the T-Nut and contacts the table, the forces change...

If the stud goes out the bottom of the T-Nut and contacts the table, the forces change, and now the slot is being jacked up. The cast iron can take a LOT less force in that direction.

A good way to prevent it is to deform the last thread on the bottom of the T-Nut so you can't screw the stud lower.

Don't let this happen to your machine!

And no, before anyone asks, this didn't happen to me, it happened to another fellow who reported it in an online forum.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.