2 months by cncdivi

Whether a CNC user plans on manufacturing a phone case using a 3D Printer or carving it out from a solid material block, it is an uncomplicated project. Furthermore, these cases serve as exceptional holiday presents.

The key is accounting for the dimensions of the phone itself. One can measure the phone, or, in the case of Apple at least, we can obtain the official blueprints they provide for organizations that want to make cases and other accessories. Apple has a page all set up for developers to access. On that page you will find a link to a document called “Case Design Guidelines for Apple Devices.” That’s where you’ll find the dimensioned drawings for all of Apple’s phones and portable devices like iPods and iPads.

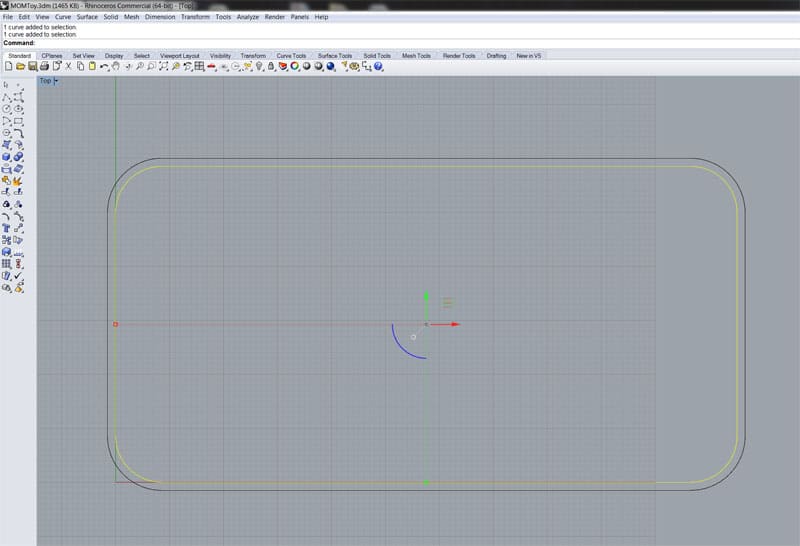

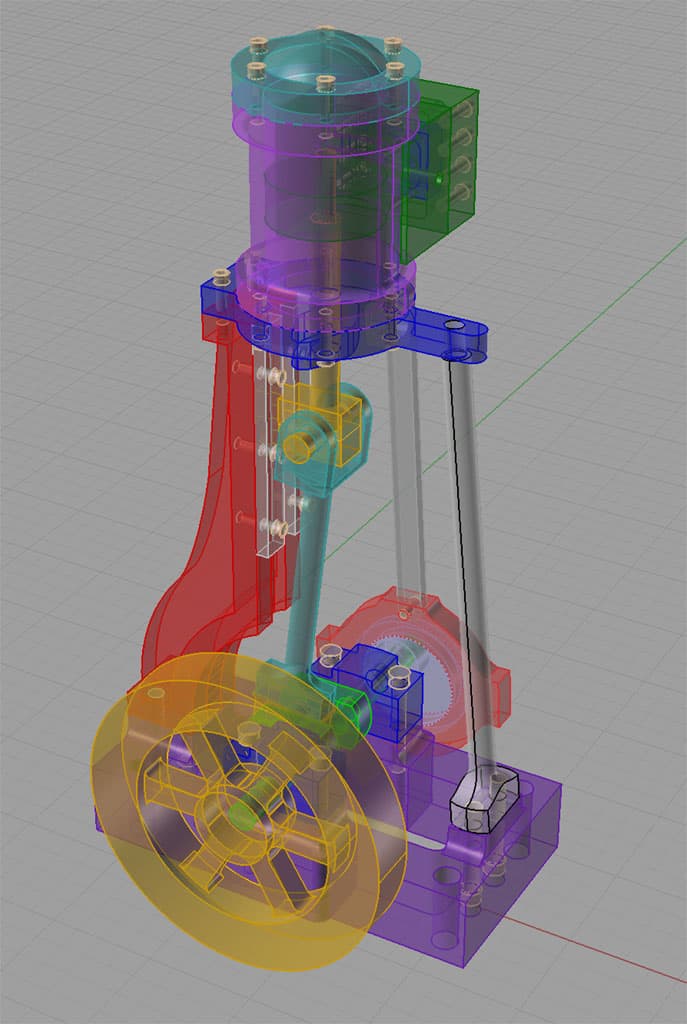

Once you get your hands on the document describing your device’s dimensions, you’ll need to put together a CAD drawing that captures the outline of the phone:

Using your CAD program, generate the outline of your phone…

I’m using Rhino3D for this project, but most any CAD program capable of 3D modelling can be used to follow along. I simply created a rectangle with the overall height and width of the phone (leaving out the buttons that protrude). I then filleted the corners to the appropriate radius. That yields the yellow outline–very easy!

The next question you’ll have to decide is how thick to make your case. For this project, I wanted a case that would not add bulk to the already svelte iPhone, and that would make it easy to operate the phone’s controls through openings in the case. So, I chose to make the case 1.5mm thick. To do that, I simply offset the inner outline by 1.5mm. All decent CAD software will have the ability to offset a line like that.

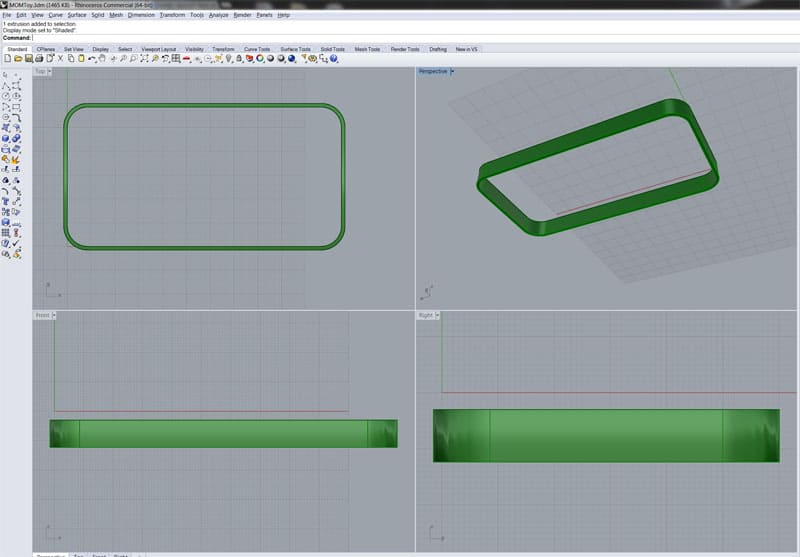

Now I have the basic outline of the case. Time to start converting it into a 3D model. In Rhino, I simply extrude that outline to the some height. This creates the sides of the case:

Phone case sides…

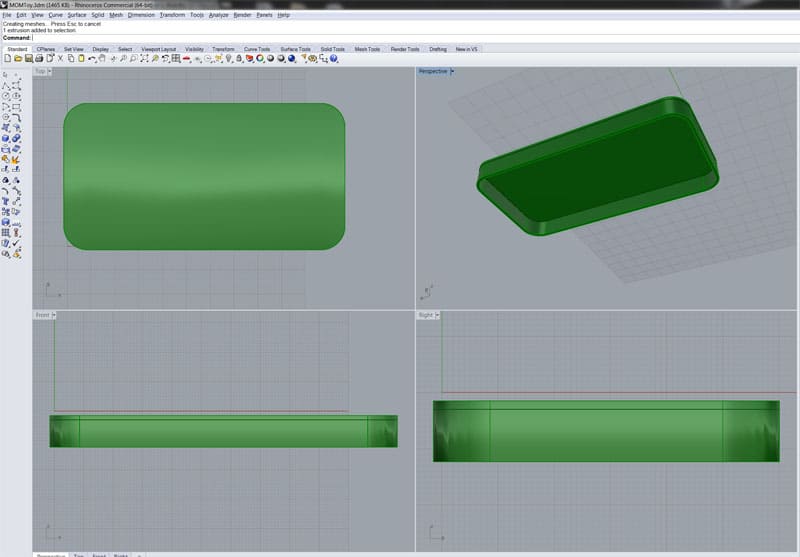

Then I extrude the outer line in the opposite direction for 1.5mm to create the bottom of the case:

Case with bottom added…

Now I have a solid model of a case. Granted, it’s generic, and I haven’t added the cutouts to access buttons, expose the camera, and so on, but it’s a start that was easily created. Go ahead and add those cutouts and you’ll have a generic case template suitable for your phone. For now, I’ll leave adding all the cutouts to the reader, but let’s have some fun personalizing this case.

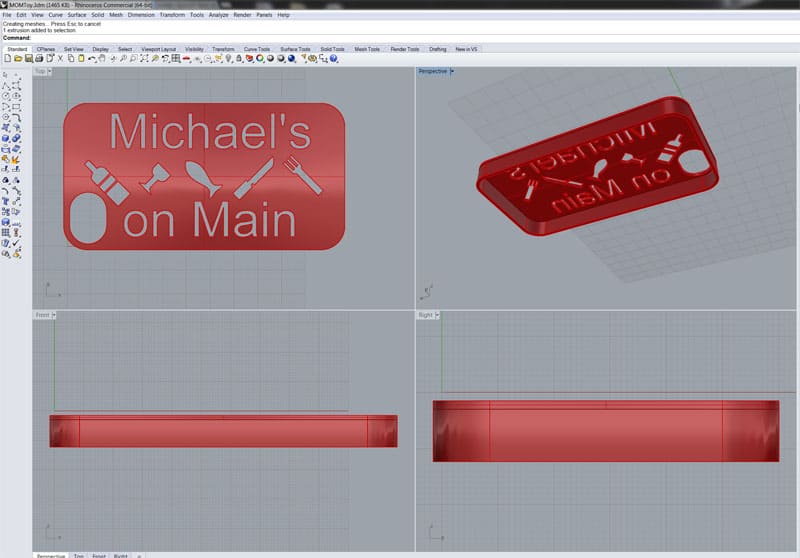

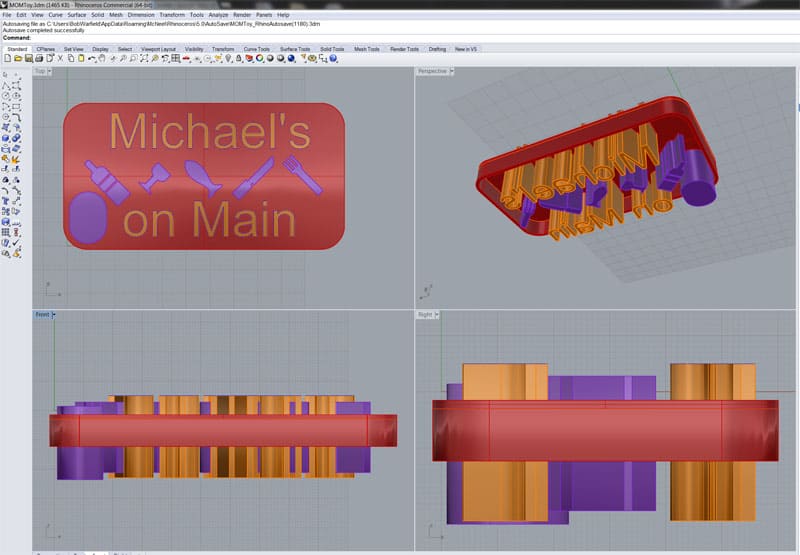

You’ll notice I drew the case face down. That’s because the personalization I want to do goes on the back of the case, and I wanted to make that part easy on myself. What I decided on was to create a custom logo’d case for a close friend who owns a local restuarant. I’ve been a Guest Chef there a number of times and I wanted to give him something fun from my world of CNC. There are a variety of things you could do to customize a case like this, but I decided to keep it simple. My task was to create cutouts in the case that create a logo of his restaurant. The finished 3D model looks like this:

Finished 3D Model of a custom phone case…

As you can see, this case is an exercise in making a cutout on the back of the case that looks like line art. The first task in doing that is to create the line art:

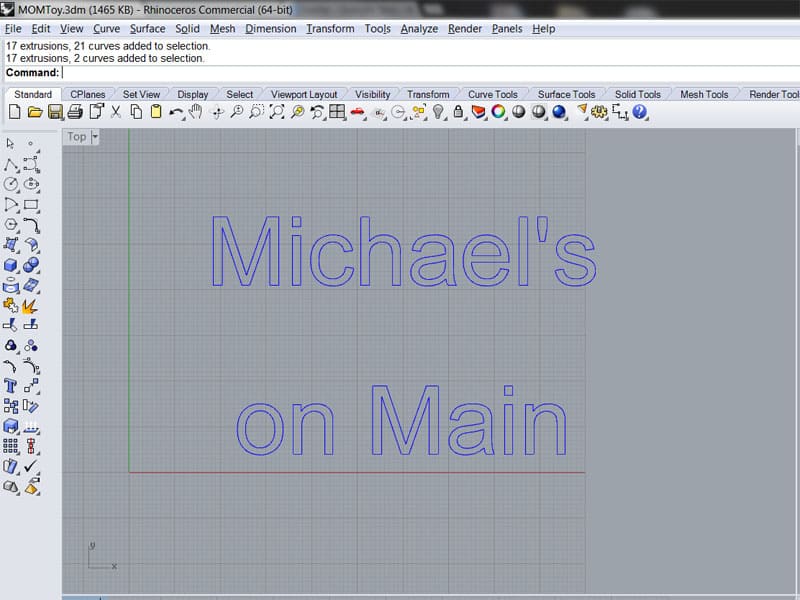

Text Outlines…

I started with a text outline. I positioned it above the bottom of the case in the Z dimension, and then I extruded it downward:

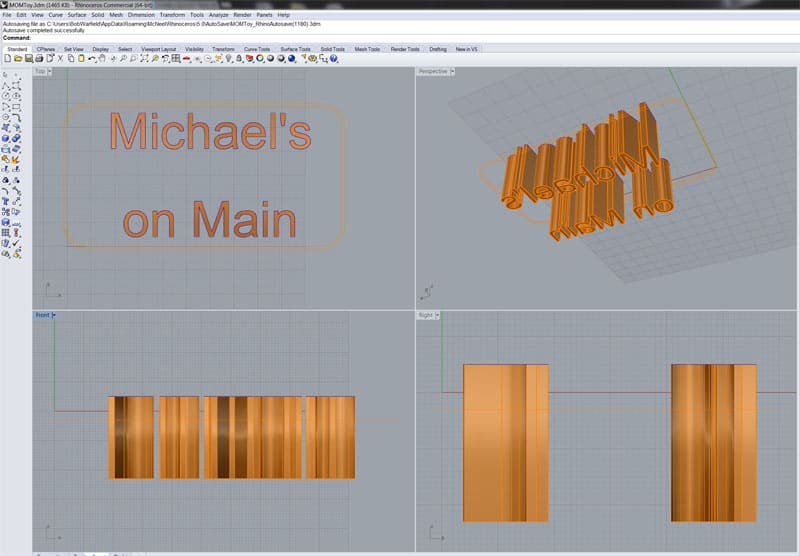

Extruding the text…

Using a similar process, I created the icons of wine bottle, glass, knife, fork, and fish:

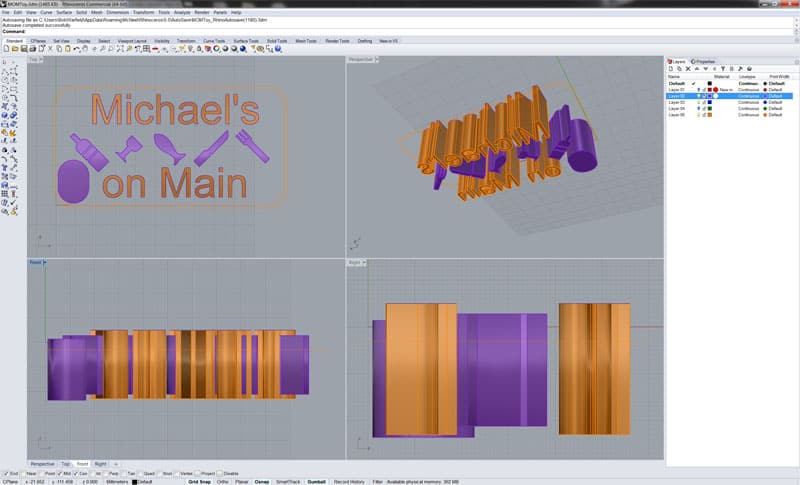

The extruded cookie cutter for the design…

Think of these extrusions as a “Cookie Cutter” that can be used to cut the design out of the back of the case. You’ll notice I added a shape for the camera cutout to make sure it wouldn’t interfere with my design.

Once I had the Cookie Cutter, I used Rhino’s Boolean Difference operation on the solids to cut the design out of the back of the case:

Subtract the Cookie Cutter from the case using a Boolean Difference…

That’s pretty much all there is to preparing a 3D model of your case suitable for 3D Printing or other CNC Work. I think I spent about an hour in total on the design work. It’s a very easy project and well suited to a beginner. Give it a try.

When we get done building our Rostock Max v2 3D Printer, this will be one of the early things we’ll want to print on it. I’ll be sure to share the results when that’s done.

This was a very simple case and I have no doubt you’ve already come up with lots of ideas to embellish your own custom phone case. Send us pictures if you make or design a case so we can share with the readers.

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![DFMA = Design for Assembly + Manufacturing [ 33 Tips, Video, PDF ] Description: Why adopt dma for your shop and increase your df.](https://www.cnccookbook.com/wp-content/uploads/2018/02/img_5a7a26e3b467f.png)

![Fixture Design Fundamental [ Do You Need a Fixture? ] A 3D model of a hydraulic cylinder created using a 4-axis CNC machine.](https://www.cnccookbook.com/wp-content/uploads/2020/04/VMC4thTombstone.jpg)

How would it hold the phone in place? Without a stopper would the phone easily slip out?

Also, what material would be used here?

I used ABS filament. It was held in place because of its tight fit. There was really no risk it could fall out.