Wow, it didn't take long to get over 500 responses, so this must be an area of interest. In this post, I will present the market share results for the different controls and compare and contrast these with our 2016 results so we can get an idea of what the market trends are. I will follow it up in a future installment that talks about customer satisfaction and some of the pros and cons of the various controls.

High End vs Low End Controls

As in 2016, the majority of respondents are using CNC Machines with higher end controls:

It seems you haven't provided any text to be rephrased. Could you please provide the text you want rephrased?

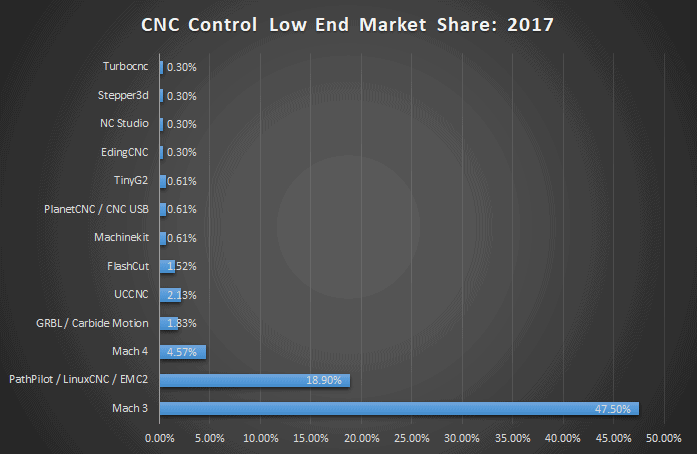

Low End Market Share

If we break down the relative share of the Low End CNC Controls, here is what we see:

If I compare that to our 2016 numbers, here are the trends I see:

- Mach 3 has gained a bit of share versus PathPilot / LinuxCNC.

- Mach 4 is hanging in there to slightly lower. Not sure what that means given it is the future of Mach 3.

- Everything else has fallen down the list.

I read that last part as there are a lot more choices in the low end world than there were a year ago. It has fragmented the market quite a lot. Inevitably, this leads to a shake out and helps consolidate the position of the market leaders (Mach3 and LinuxCNC), but it takes a while for the shakeout to occur.

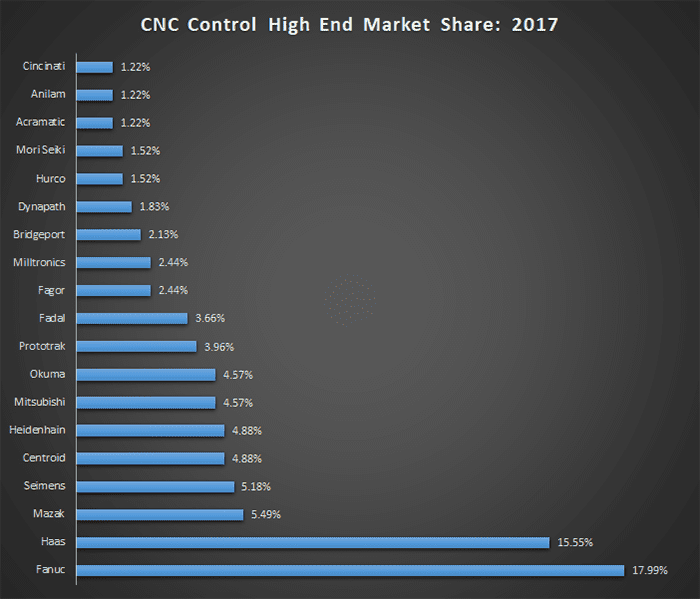

High End CNC Control Market Share

Here are the High End Control numbers:

Controls with more than 1% market share...

Those are just the controls with more than 1% market share-more than 5 responses on the survey.

There are two few responses for the other controls to make a statistically significant comparison, but there were some 27 additional controls called out. The world of CNC Controls is nothing if not diverse!

If I compare these results versus 2016's survey, here's what we can see for trends:

- Fanuc keeps the top position, though their share has declined slightly from 21.5% to 17.99%

- Haas moved up quite a lot, from 3rd place 9% share to 2nd place 15.55%.

- Siemens, by contrast, moved down from 2nd place 11% to 4th place 5.18%.

- Centroid is another notable climber, moving from 14th place up to 5th.

- The next tier down with players like Mazak, Heidenhain, Mitsubishi, Okuma, Prototrak, Fadal, and Fagor are relatively unchanged.

Conclusion

It's always iffy to put too much stock in relative market moves. We may survey next year and find the places have changed again.

Some of these motions reflect real competitive movement and some is just noise.

What's clear is that Fanuc and Haas are way ahead of everyone else at the High End while Mach 3 and PathPilot / LinucCNC rule the Low End.

For the next installment, I dig into the results on customer satisfaction for the different controls.

[ CNC Control: Customer Satisfaction ]

To make sure you don’t miss out on the future installments, be sure you’re on our weekly email newsletter. There’s no charge and you can sign up right below. You’ll get all our premium content for free plus a weekly email digest of all our new articles.

Meanwhile, what’s your take on the results? Tell us in the comments below.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.