5 axis CNC machines are the pinnacle of milling machine sophistication. They're the most expensive machines to purchase, and due to the complex motions involved, even more cost is involved with the need for the most sophisticated 5 axis CAM packages available. Find out why they're worth it here.

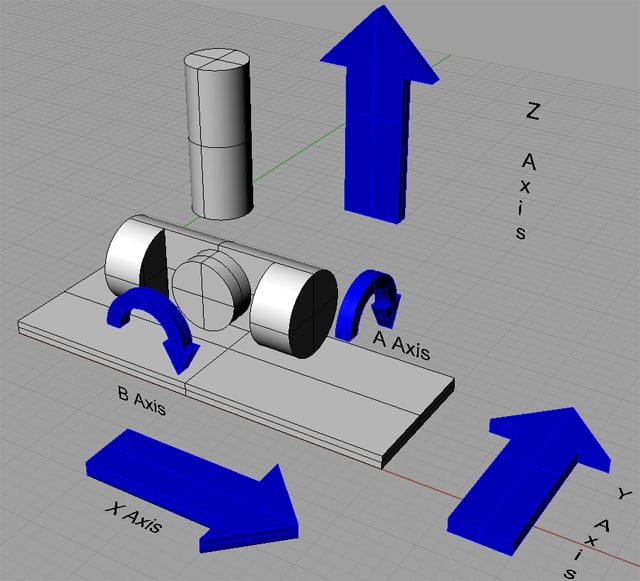

Let's start by getting an idea of what a 5-Axis machine is and what differentiates it from more common 3- and 4-Axis machining centers. With a 5-axis machine, you get (duh!) 2 more axes of motion versus a 3-axis machine. Here's what those motions look like:

5 Axis CNC Motions

It's the A- and B-Axis that are new in this configuration. What they let a 5-axis machine do is position the spindle (represented by the vertical cylinder to the left of the Z-Axis arrow) over a much greater percentage of the total surface area of the part.

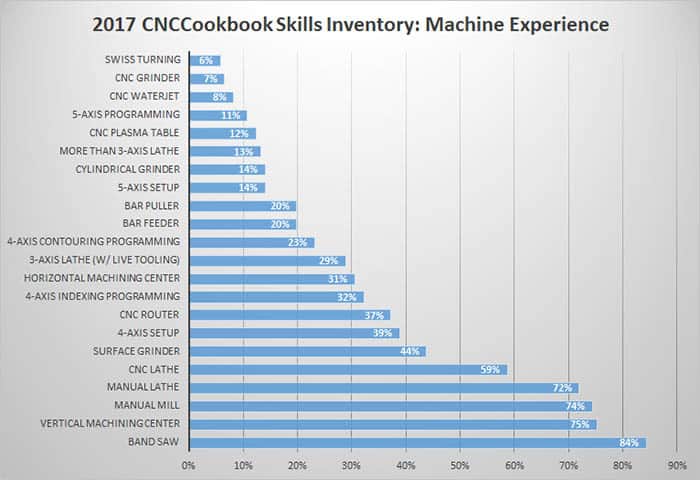

Just how common is 5-axis work? I wouldn't call it rare, but the respondents to our CNC Skills survey reported that only 14% of them were skilled in 5-axis setup. 4-axis work, by contrast, has been done by 39% of the respondents, so it is much more common:

5-Axis machining is often divided into two categories-Continuous or Simultaneous 5-Axis and 3 + 2 Machining. With 3 + 2 (sometimes called "5-Sided Machining"), the actual chip cutting is done just as with a 3-axis machine, and the other 2 axes are locked so they cannot move. 3 + 2 gives some, but not all, the benefits of Continuous 5-Axis Machining.

3 + 2 is easier to program, but Continous 5-Axis can have better surface finish, longer tool life, and can allow tools to reach difficult places more smoothly.

There are a number of different geometric configurations used to implement 5-axis motion. Sometimes we rotate the part, sometimes we rotate the spindle, sometimes it's a combination. We'll talk more about these configurations at the end of this article.

Enough discussion of what 5-axis is, let's talk about it's powerful benefits:

#1 - 5-Axis CNC is Uber Cool!

I admit, this is not a business-worthy benefit, but how can you not get excited by videos like this:

#2 - Reduced Machining Time with 5-Axis CNC

Okay, this is a little more like it-reduced machining time. What shop wouldn't want that benefit?

The time is reduced because a 5-axis machine can use a flat bottom endmill and by maintaining perpendicularity to the surface (there's a reason the tool or part swivels constantly in the video), you can use full diameter step-over instead of having to use little short stepovers more common to ballnose endmills. Those of you running very small stepovers to generate a nice smooth surface can really appreciate the savings in this.

Here's another advantage of 5-Axis that can reduce machining time-shorter tools. With a 5-axis, you can tilt the workpiece so shorter tools clear other features of the part. Shorter tools are more rigid, so you can machine faster without incurring excessive tool deflection, which is very bad for tool life.

#3 - Better Surface Finish = Less Manual Cleanup Work

No more little scallops when you use that flat bottom endmill. No more cleanup with elbow grease and abrasives. Shorter tools with less deflection means less chatter and better surface finishes. Sweet!

#4 - Fewer Setups

When you can get at nearly every face of the part except for the very bottom, you have fewer setups needed. Another big savings for 5 axis CNC.

#5 - Better Accuracy

Every time you change a setup, a little error will creep in. With fewer setups, or perhaps even just 1 setup, this source of error is eliminated.

#6 - Machine Parts Not Otherwise Possible

Let's face it: something like the helmet shown in the video wouldn't even be possible without 5 Axis CNC. Many parts that require a lot of undercutting will be much more difficult without 5 Axis CNC.

#7 - Less Competition

Not every shop is going to even have a 5 axis machine and the expertise needed to make it sing. Having the only 5-Axis CNC capability in your region can give you a real leg up over the competition-it helps to have an edge! Just be sure the work in your area can benefit from it.

What's the ROI of a 5-Axis CNC Machine?

Hurco has a free worksheet you can download that let's you estimate the ROI of a 5-axis machine for the work you do:

[ Hurco 5-Axis ROI Worksheet ]

Types of 5 Axis CNC Machine

First, let's take a look at the motions we're looking for:

The first possibility is the Swivel Head 5 Axis CNC. This is the style depicted in the video of the motorcycle helmet above. There are several different variations on this used for purpose-built 5 Axis CNC machines. Here's a good discussion of the benefits of a Swivel Rotate style machine:

We can also retrofit 5 Axis CNC to an existing VMC in a couple of ways:

The little sketch depicts what is commonly called a Trunion Table. Think of it as a 4th axis with a rotating axis attached at right angles. A Trunion Table is one of the easiest ways to refit 5 axis motion to a conventional VMC.

Here's a good discussion of the benefits of the Trunion Table style of 5-Axis CNC:

Another retrofit approach uses a 5 Axis CNC Head mounted in the taper of a conventional 3 Axis VMC.

5 Axis CNC Head

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.