Keeping up with the latest from Kenneth Maxon and his exciting robot endeavors is always a delight. His CNC workshop is well stocked, and he does sophisticated, exquisitely detailed work. Check out this photographic record of his most recent project he shared for all to appreciate:

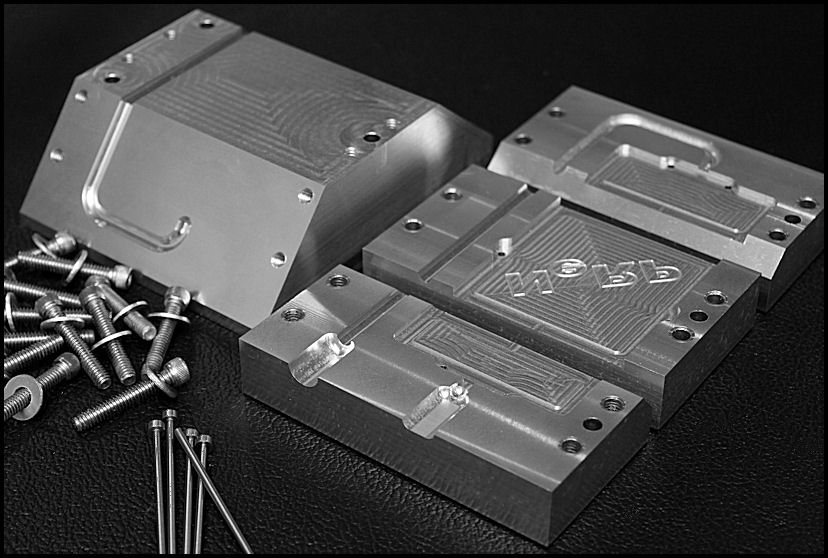

Here's a view of the mold which is in 4 parts. It's capable of making parts in 2 different configurations...

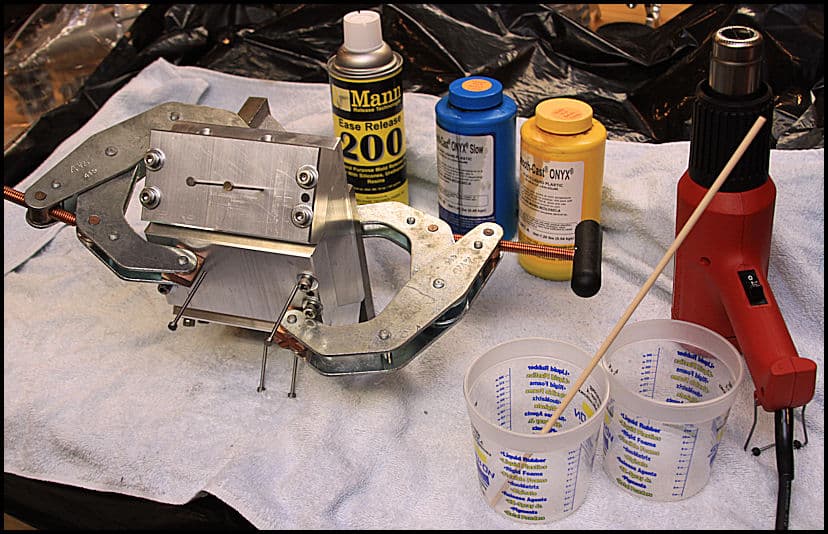

Mold parts clamped together and ready for the 2-part polyurethane treatment...

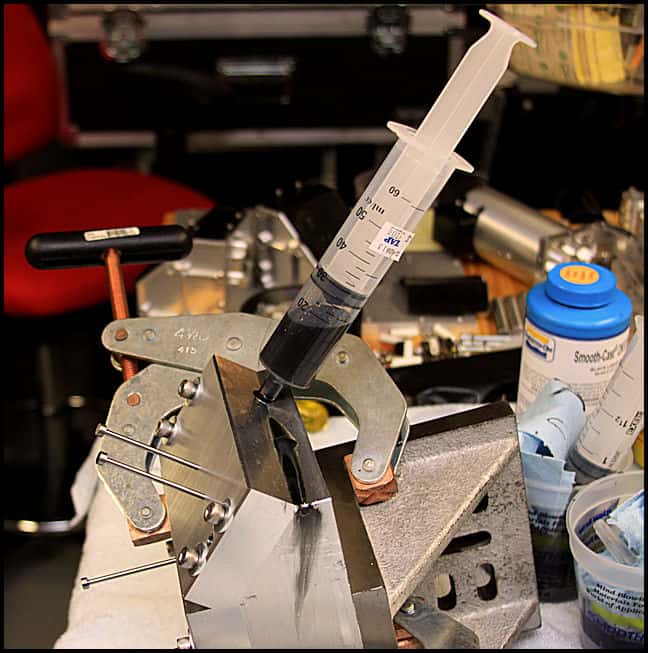

The 2-part plastic is not poured, it is injected. Kenneth says:

I'm often asked how one gets the material to ‘pour' with such a high surface area to cross section aspect ratio. The trick comes in using a large bore syrenge to push the material through the tool. This also helps to cary some of the smaller air bubbles through and out by letting excess material overflow from the air relief.

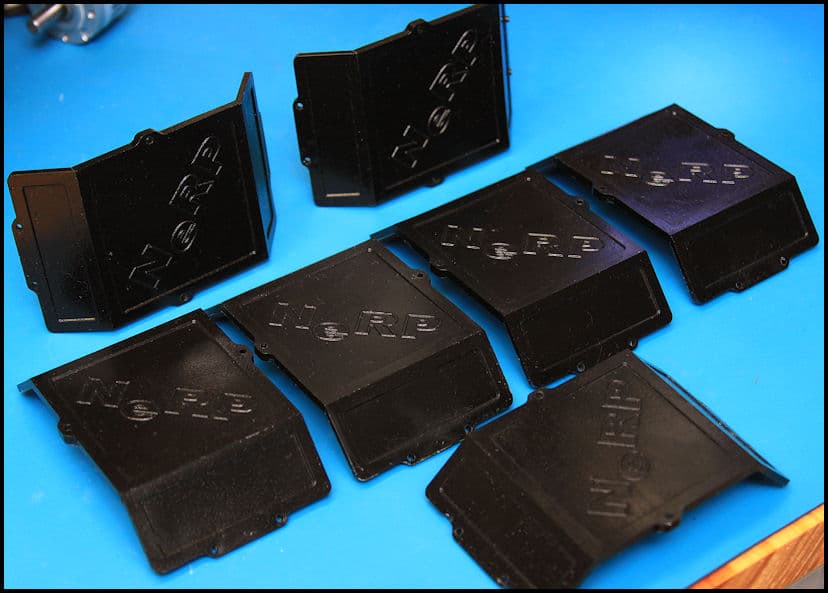

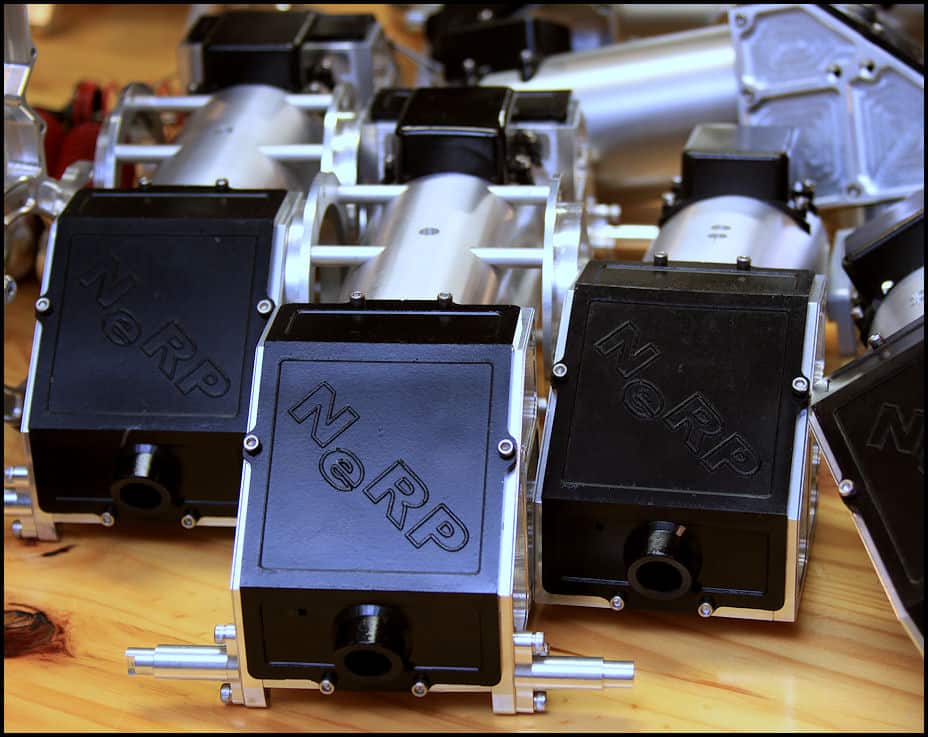

Here's what the parts look like after the plastic has cured, first configuration...

And here's the second configuration. Kenneth writes:

After the first part comes out it is pretty easy to get a nice surface finish on all of the parts that follow. The first part comes out a bit ratty as, no matter how well the tool is cleaned, the molding process pulls ‘magic' chips out of it. Additionally, the 2-part materials and the mold release wax have a small chemical inter-action with the soap film left when washing the tool. Once the first part is pulled from the tool, all of the following parts come out with a great surface finish like those shown in the photo.

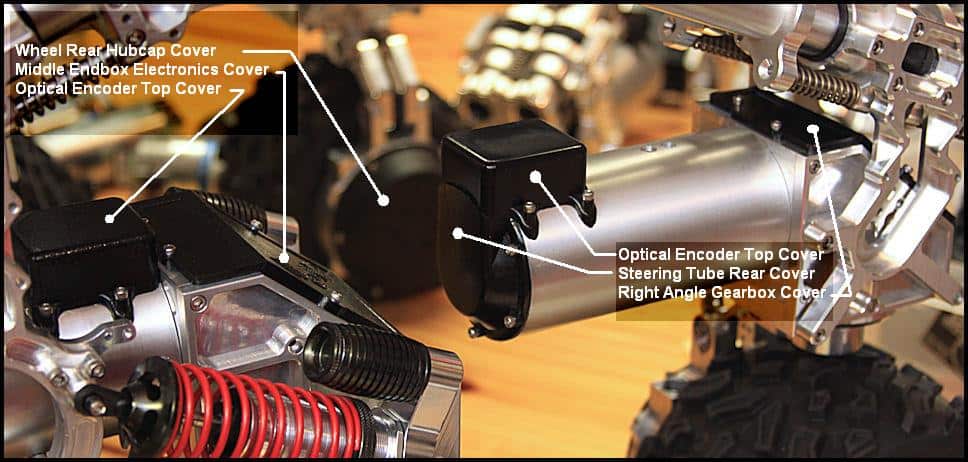

This photo shows the molded parts installed on Kenneth's robots.,.

Details on how these molds were machined can be had on Kenneth site.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.