Before initiating my own endeavors, I find it useful to check out how others have dealt with similar issues. This page simply offers a collection of pictures demonstrating how various individuals have constructed housings for their CNC electronics. If you're curious about the specifics of the electronics that constitute a CNC controller, we have an additional article covering that subject.

Very nicely done box based on a Gecko 540. The box is a Bud Industries "PortaCab"...

That's a big ole transformer! Looks like the front panel is mostly concerned with the DC supply...

Outback we have a nice set of connectors and a very professional appearance. The Gecko 540 really makes it possible to package things tightly...

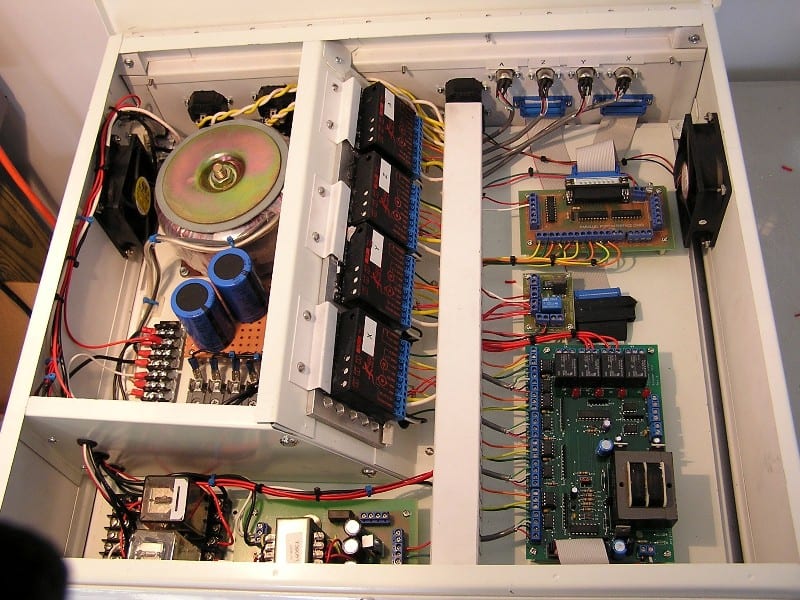

Note the rail system to hold the Gecko drives in the middle, the box around the power supply, fuses for each Gecko, and the controller boards all in their own area. Very nice layout! Mounting those Geckos on a near vertical panel saves a lot of space.

Slight variation on the same theme. Relays are at bottom. Also note the aluminum plate to help as a heat sink for the Geckos.

Nice little power supply bracket, in'it?

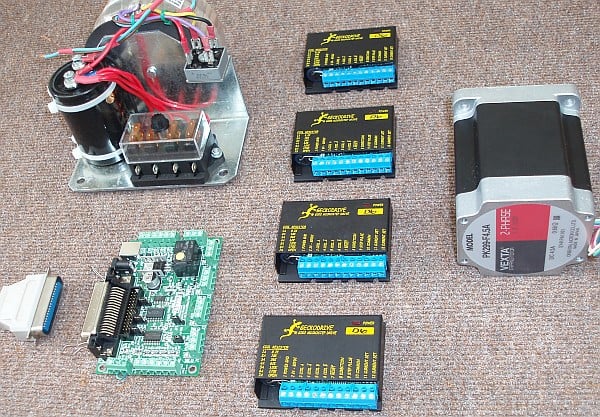

All this goes in the orange box. Note the 35mm DIN rail used to mount the goodies. There is room underneath it to run wires...

Nice how everything has a little connector with no bare wires and the cables are bundled together with cable ties. A little judicious heat shrink tubing also helps neatness. And the Geckos are on a big chunk o' aluminum so they'll stay cool.

Ahhhh! Now that color is more my speed!

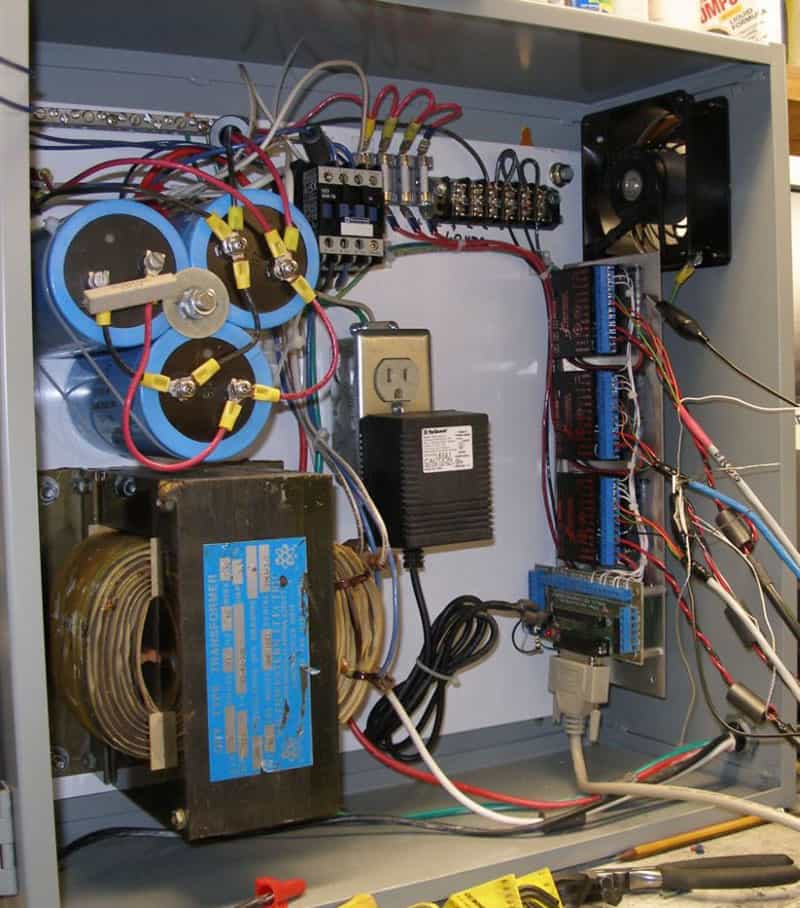

Another NEMA box supply. Geckos on a separate plate. AC outlet for all wart. No opto isolation on breakout board? Note ferrite beads for noise reduction.

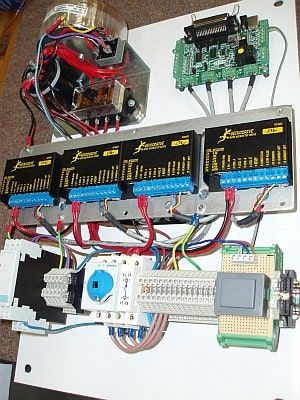

Here's an example box that has a breakout card, the geckos, motor control circuitry, and the DC power supply. This one was made by Widgitmaster. What a nice compact presentation!

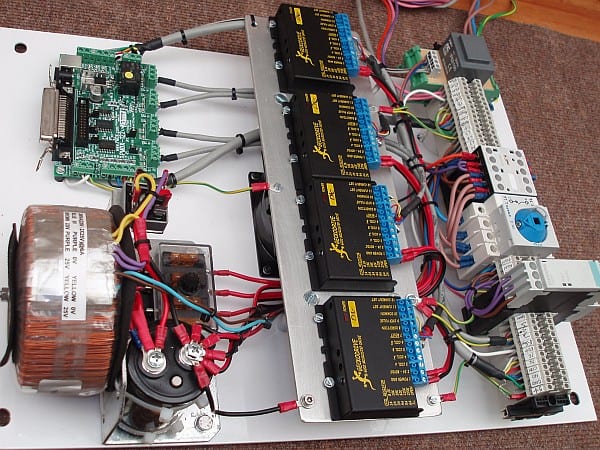

Here is rack system is pretty similar to my CNC lathe's rack chassis. There are several features of his case that I really like. First, It was definitely simpler to just mount the Geckos to the wall rather than use the heatsink I did. Second, I like bringing out the fuses with pilots to the front panel for all axes. I think adding a disable switch to each axis would be nice as well, though it wouldn't get used an awful lot. For my upcoming IH mill CNC conversion, I intend to use panel mounted fuses with ammeters to show load on each spindle as well as disable switches.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.