Thank you to everyone who participated in our 2021 End Mill Survey! With nearly 300 votes cast for 97 different brands, we're excited to share the results.

To make it easier to identify trends, we're using the same format as our 2018 End Mill Survey. The results are divided into three tiers:

- Tier 1: The most popular brands, accounting for 70% of the votes.

- Tier 2: Brands that add another 25% of the votes. Combined, Tiers 1 and 2 represent 95% of the total votes.

- Tier 3: Lesser-known brands that make up the remaining 5% of the votes. We won't discuss these brands in detail as the sample size is too small to draw meaningful conclusions, other than their lower popularity among the CNCCookbook audience.

Let's dive into the results!

Thanks to everyone who participated in our 2021 End Mill Survey (almost 300 votes cast for 97 brands), we’re ready to present the results.

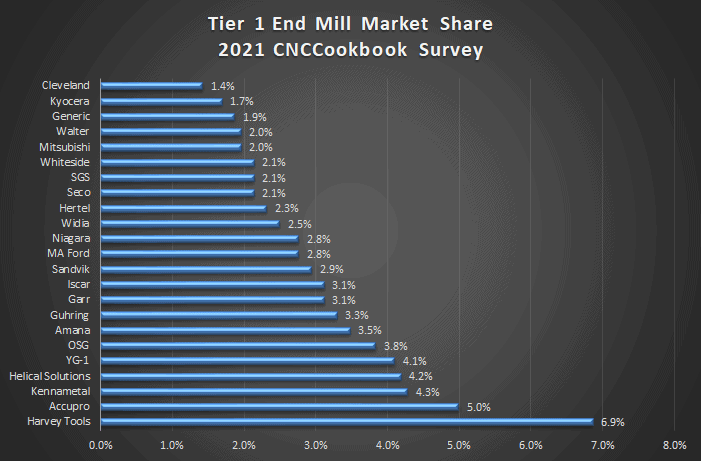

First Tier End Mill Brands

Collectively, this tier garnered 70% of the votes, so they have most of the market share for this audience.

Here is how you voted for these end mills:

The top 3 brands were Harvey Tools, Accupro, and Kennametal. Compared to last survey, Kennametal moved up 4 places to replace OSG. It had been #7 in 2018 while Niagara was #3.

Accupro is MSC’s house brand in case you didn’t know.

Other movements from 2018 – 2021:

- Helical Solutions is up from #10 to #4.

- YG-1 is up from #6 to #5.

- Amana is up from #14 to #7.

- Guhring is up from #9 to #8.

A lot of this is normal market fluctuation, but clearly some brands are moving far enough to indicate they’ve made progress in 2021.

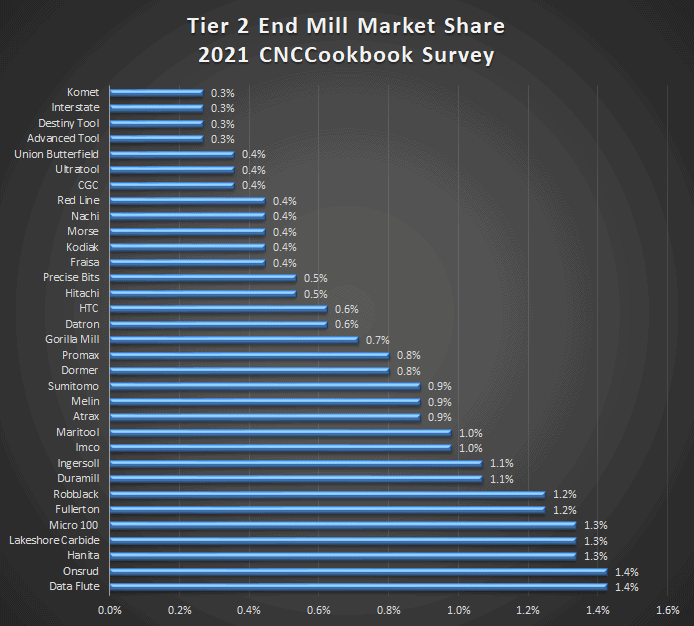

Second Tier End Mill Brands

Collectively, the second tier garnered another 25% of the votes, which brings the total market share of First and Second Tier to 95%.

Here is how you voted for these end mills:

There are a lot of great brands in the second tier.

The remaining 5%, representing the Third Tier, had 40 brands, each of which garnered just 3 or fewer votes. That’s too little participation to give us any statistically significant trends.

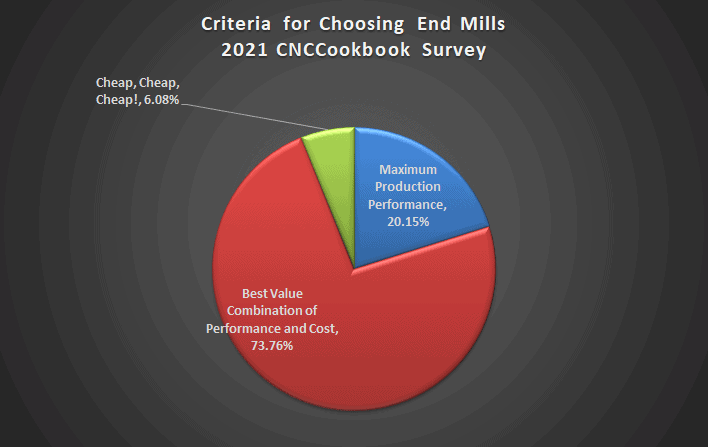

Why are You Buying?

Obviously just straight up brand popularity doesn’t tell the whole story on which end mills might be worth looking into. We also asked the survey respondents why they were buying with 3 choices:

- Maximize production performance

- Best balance of value + performance

- Cheapest

Here’s the result:

The most popular category by far was choosing end mills with the best value combination of performance vs cost. That was followed by a smaller audience seeking maximum production performance.

How you're thinking about the value the tool brings is going to affect your choices for sure. But consider this:

Here's how the costs break down according to Sandvik on a typical CNC Job:

Variable costs

Costs incurred only under production

• Cutting tools (3%)

• Workpiece materials (17%)

Fixed Costs

Costs incurred at all times

• Machinery (27%)

• Labor (31%)

• Buildings & administration (22%)

As you can see, cutting tools are only about 3% of your budget. Let's say you have found some super high performance cutting tools that cost 2x what you had spent, but you can increase your cutting speed by 20%. In effect, increasing your cutting speed also increases your capacity by 20%. If you have enough business, you can take on that much more work.

Or, you can view it as saving 20% of the Fixed Costs (hourly) you're assigning to a particular job. Again, if you have the ability to use the extra capacity you've created, you can translate your time savings either into more profit or lower bids which gives you more business.

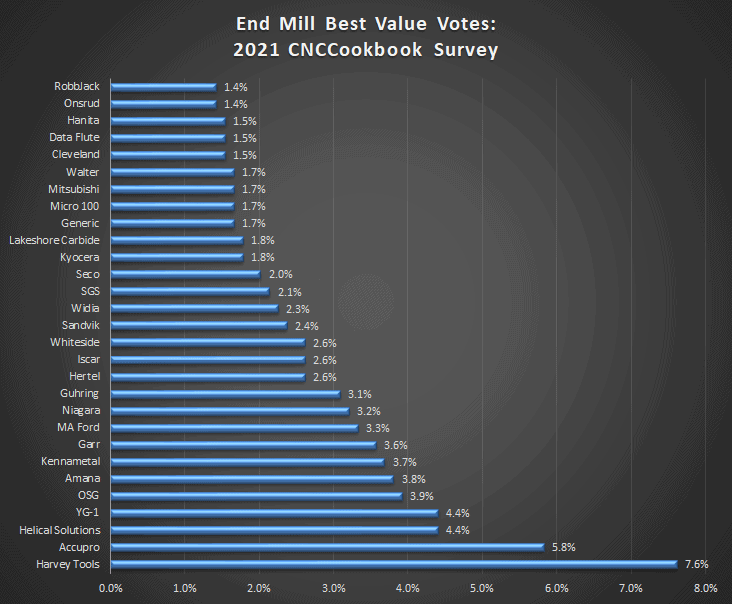

Best Combination of Performance and Price

For our most popular category, folks are trying to balance performance versus price. They want the best end mill value for their money, in other words. Here are the results:

The best end mill values were from Harvey Tools, Accupro (MSC’s house brand) and Helical Solutions. Compared to 2018, we see the following moves:

Risers

- Helical Solutions went from #12 to #3

- Amana from #14 to #6

- OSG from #5 to #4. YG-1 from #5 to #4

Drops

- Niagara from #3 to #10

- Garr from #6 to #8

- Iscar from #8 to #13

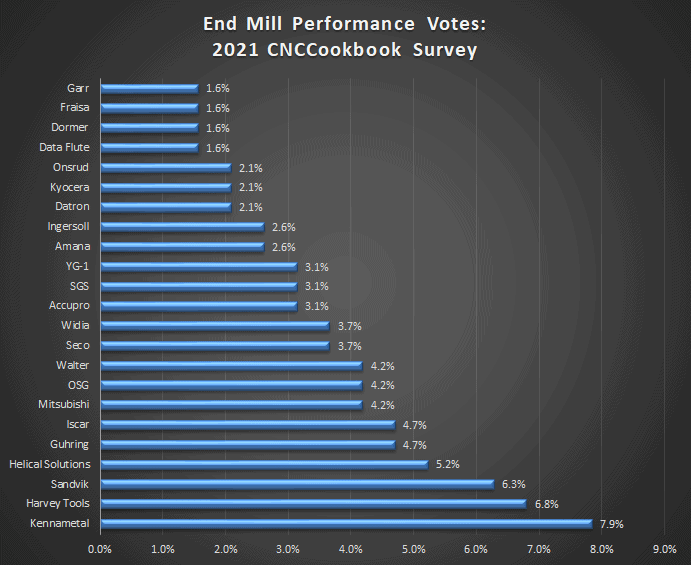

Performance End Mills

Which end mills are the high performance crowd selecting?

The most popular brands for all-out performance were Kennametal, Harvey Tools, and Sandvik. Here's a breakdown on the Risers and Drops vs 2018:

Risers

- Kennametal rose from #4 to #1.

- Sandvik rose from #16 to #3.

- Guhring rose from #8 to #5.

- Iscar rose from #12 to #6.

Drops

- OSG fell from #2 to #8.

- Garr fell from #3 to #23.

- MA Ford went from #6 to not registering on the chart.

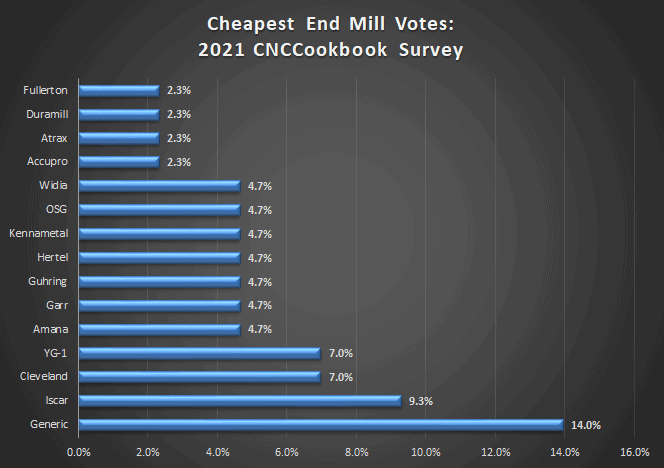

Cheapskates

Hey, what if you just want the cheapest possible end mills, even when it may mean compromising performance or quality?

Listen, sometimes it makes sense. Here’s the brands you choose for this category:

It’s fascinating to see some of the same end mill brands doing well here as did well on Value or Performance. Does that make sense?

It all depends on how you define “Cheap”. If it’s literally the unit cost of an endmill being lowest, then it makes no sense. But, if it is the cheapest cost to remove say a cubic inch of material, then it makes perfect sense to see some end mills from the higher performance categories showing up. I have heard informally, for example, that YG-1 end mills do a great job at their price point.

And of course, it makes sense that the Generic end mills from China win the category by a wide margin.

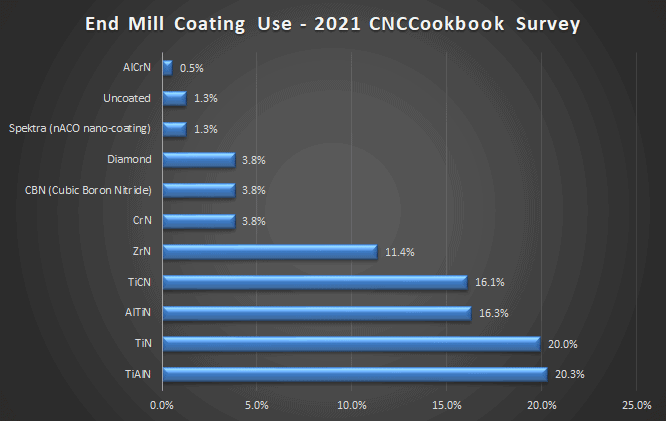

Coatings

Another question we asked on our survey was which coatings you prefer to purchase. Coatings can increase the performance of end mills considerably in terms of Tool Life and Material Removal Rates, so it’s no surprise that coatings are very popular. Here are your choices:

In 2018, 2.7% of the audience preferred uncoated End Mills. In 2021, only 1.3% use uncoated endmills. The most popular coatings are TiAlN, TiN, and AlTiN.

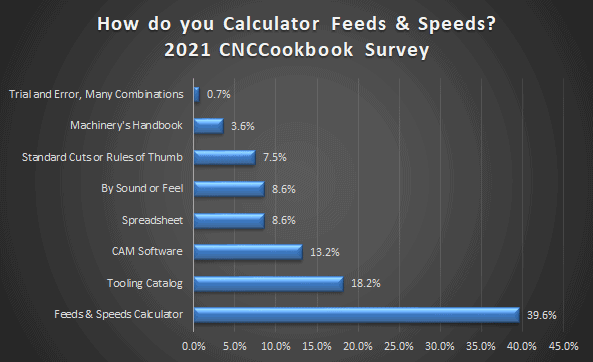

How CNC Machinists Calculator Feeds and Speeds

Feeds & Speeds Calculators are by far the most popular method-over 2X as popular as the #2 method which is to use the Tooling Catalogs to give you Manufacturer's Recommendations. This number is up from 24.8% to 39.6% since 2018, in fact.

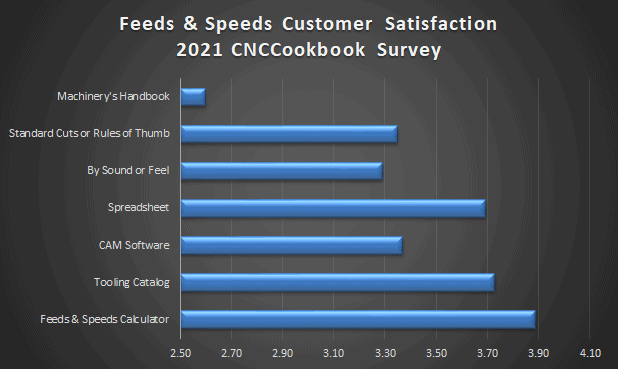

Something new is we asked about Customer Satisfaction. In other words, "How well are your feeds and speeds working with that method of calculation?"

Here are the results:

Not only is a Feeds and Speeds Calculator the most popular method, it also works the best. In fact, from Best to Worst here's what we have:

- Feeds & Speeds Calculator

- Tooling Catalog / Manufacturer's Recommendations: Not suprising that the Mfg has something to contribute. But remember, you can provide that info to make a Feeds and Speeds Calculator work even better.

- Spreadsheet: I started out with a spreadsheet before I wrote G-Wizard.

- CAM Software is tied with Rules of Thumb (Experience also goes here). It really doesn't work all that well.

- By Sound or Feel is 2nd to last. This approach is something of a myth. It sort of works for old Bridgeport manual machines, but not on a modern CNC.

- By far the worst approach is Machinery's Handbook. It has it's place, but Feeds and Speeds are not that place.

Got Milk?

Now you’ve got a lot more information about the which End Mill brands are the most popular based on which type of buyer you are (performance, value, or super cost-conscious). But, in the true spirit of the old Got Milk ad campaigns, I have to ask you in all sincerity:

“Do you have a good Feeds and Speeds Calculator?”

I mean that very seriously, because End Mills live or die based on whether you use them with the best Feeds and Speeds. End Mills can be very costly, and feeds and speeds calculators can make a huge difference to both Tool Life and Material Removal Rates (for faster cycle times).

As we've seen, a good Feeds and Speed Calculator is both the most common and the most well loved solution to the problem.

Here are the improvements users of our G-Wizard Calculator software told us they got versus whatever method they used before:

56%

Longer Tool Life

46%

Faster Cutting Speed

94%

Time Saved on Feeds & Speeds

Considering the G-Wizard Feeds and Speeds Calculator can be had for as little as $79, those are some pretty amazing results that you can start experiencing in just minutes after installing a free 30-day trial. In fact, most good quality end mills cost all most as much as G-Wizard, so it pays for itself in a hurry. Give it a try.

Improve My Feeds and Speeds For

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.