Note: This post relies heavily on material contributed by C.R. Onsrud, who have their own article about how to manufacture Sneeze Guards. They're one of the premier makers of industrial CNC Routers. Special thanks to C.R. Onsrud for allowing us to use their material! Another group who helped with some information is Fabricators Fighting Covid-19. Lastly, Pittsburg State University contributed some photos.

There are a number of types of PPE (personal protective equipment) that will help reduce the likelihood of Covid-19 infection. And there is increased demand for PPE.

As states and towns reopen, we're getting an uptick in cases. The solution is to back off and try again, and to implement even more measures to reduce the spread. That means even more demand for PPE.

The more demand, the more costly and hard to get PPE becomes for the folks that need this PPE gear. As a CNC'er, you can help. There are a number of different types of PPE that you can manufacture, depending on what sorts of CNC machines you have available.

Whether you're looking for new avenues of business in becoming a PPE Supplier or you just want to make sure local businesses can get the types of PPE they need without being gouged, it's an opportunity to do some good.

Types of Personal Protective Equipment (PPE)

There are basically two types of PPE that are readily manufactured via CNC-full face shields and sneeze guards.

Full Face Shields

You have not provided any text for the assistant to rephrase. Please submit the text and try again.

Full Face Shields (also "Medical Face Shields") are an important part of the PPE kit. They prevent any aerosol droplets from directly landing on the face or from being expelled directly ahead by the wearer. Some small droplets can still make their way around the edges of the full face shield, but the overall exposure is greatly reduced. As such, they are a must for medical and other personnel that directly deal with those potentially infected with Covid-19.

While the true effectiveness of Full Face Shields is not known with certainty, there have been tests that suggest they can reduce the exposure to typical aerosol flu droplets by 92-96%. That's a substantial benefit. However, smaller droplet sizes reduce that effectiveness to 68%, still valuable.

Sneeze Guards

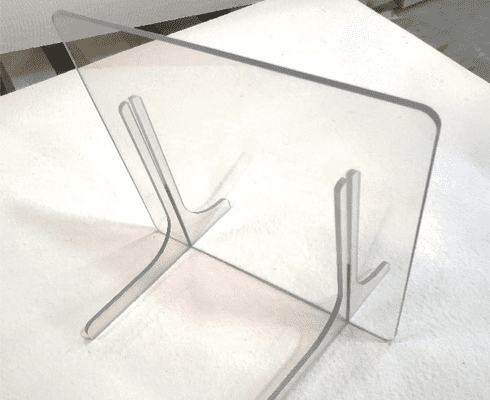

A simple portable sneeze guard...

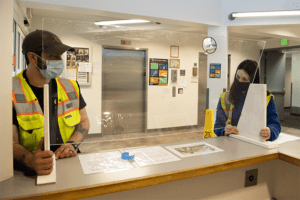

Sneeze Guards perform essentially the same role as Full Face Shields, but nobody has to wear a Face Shield. As such, they're friendlier in environments where they make sense. Any situation where you need to walk up to a counter and talk to someone is a potential Sneeze Guard application. There are portable sneeze guards, counter sneeze guards, and what I would call "partition sneeze guards."

You can use floor standing / partition sneeze guards to protect coworkers that have to sit near each other in regular desks.

PPE Requirements and PPE Standards

When manufacturing PPE, it's important to be aware of any standards or requirements that dictate how they need to be made.

Face Shield Requirements

While there are no official standards per se, there are definitely recommendations as well as some requirements for labeling and types of materials.

A wide variety of suspension systems are available. They range from full adjustable systems that are meant to be permanent and have just the clear part replaced to disposable systems. From a comfort standpoint, try to at least make sure there is some foam against the forehead.

The frame must offset the visor far enough from the face to permit wearing eyeglasses and potential N95 respirator.

Resources

- FDA letter authorizing emergency use and detailing requirements for Face Shields that mostly involve proper labeling and use of materials that suit flammability requirements.

Face Shield Materials

But I want to discourage polycarbonate as it is too brittle and cracks easily.

You'll also need foam pads that are comfortable and seal the top of the Face Shield to the wearer's forehead. You can hot glue the pads to the clear visors.

Lastly, you need an elastic band to hold the Face Shield on the head. Typically, the elastic is fed through holes in the Face Shield and secured by sewing or stapling to itself.

You can obtain elastic from local craft and sewing stores or commercial distributors of upholstery supplies or textile suppliers. Alternatively, you could also use silicone instead of elastic for the band. Just make sure it is latex-free silicone as many are allergic to latex. If you're going the silicone route, look for 1.4-1.6mm thickness, Shore 50A.

Face Shield DXF Files and Patterns

Just Google "Face Shield DXF Files" and tons of them come up. Here are a few I checked out and found good:

- Steel Case: Yup, the furniture guys.

- Apple: The computer guys.

- East Tennessee State University: Downloadable drawings.

There are many more. Download and modify to meet your needs.

Sneeze Guard Requirements

First, what requirements exist vary from state to state, so there is no universal standard. That said, there is an ANSI standard available from NSF. It is possible to have your sneeze guards certified to compliance with this standard.

First, what requirements exist vary from state to state, so there is no universal standard. That said, there is an ANSI standard available from NSF. It is possible to have your sneeze guards certified to compliance with this standard.

Some of the basic requirements revolve around height, which we'll cover below, and some obvious things like:

- The Sneeze guard height needs to at least be tall enough for the average customer, who may be 6 feet tall.

- The material used for the Sneeze Guard should not be subject to chipping (like most glass). If you are using materials that chip, the edges must be protected with tight fitting channels.

- A vertical barrier should be provided at either end of a sneeze guard (also called a "Food Shield" by NSF). This side barrier should be a minimum of 18" deep. The overall height of the side barrier and mounting should be such that it matches the top and bottom edges of the forward facing guard. If the Sneeze Guard is mounted 3" or less from a wall, no side barrier is needed on that side.

- If it is necessary to reach under the sneeze guard a maximum gap of 13" is permitted.

- Anything that must avoid contamination (like food) must be at least 3/4 of the maximum gap allowed for reaching under the barrier.

These are good starting guidelines. More are available from this NSF downloadable pdf that cover specific situations.

Contact your local Health Department for the guidelines they enforce in your area.

Sneeze Guard Materials

Tempered glass and various plastics are suitable materials for Sneeze Guards. As mentioned, if the material is subject to chipping, you need to protect the edges with deep guide rails. Alternately, use rounded edges to prevent chipping.

Sneeze Guard DXF Files

Much like Medical Face Shields, you can download DXF files for sneeze guards from a variety of sources, such as the Fabricators Fighting Covid-19 site.

Sneeze Guards are apt to be much more custom than Face Shields, so you're going to want to get your own CAD models going that you can update to customize as needed. You're basically looking at a family of parts that include:

- Legs and feet to hold the Sneeze Guard

- Brackets or slots to attach the Sneeze Guard to the Legs and Feet

- Templates for cutting out the Sneeze Guard itself.

Spend a little time getting ideas by browsing the web, borrow some DXF files, and start modifying to create your own designs. If yours look better or have other features and advantages you'll have an advantage in the sales call.

Be sure to consider custom touches like adding the customer's logo or other messages via engraving, laser, or masking off and sand blasting.

Sneeze Guard Parts, Brackets and Hardware

Brackets and hardware are intended to hold the transparent panels in the correct orientation. Sneeze Guard Hardware is available from a variety of sources. Here are a few we found

- DK Hardware has a page dedicated to Sneeze Guard hardware including posts, glass clips to hold glass, edge channels and more.

- The Webstaurant Store also has hardware as well as finished sub-assemblies.

- CR Laurence is another.

This type of hardware is mostly focused on building permanent sneeze guards for restaurants and the like. If you're building portable or temporary sneeze guards, you'll likely be making all the parts in your shop and perhaps just using a little hardware, such as glass clips.

PPE Manufacturing

Suggested Machinery

If you are a machinist, machine shop owner, entrepreneur, or maker looking to help satisfy the demand for PPE, it’s important to make sure you select the right machine based on both your current and future needs. Sneeze guards can be designed in a variety of shapes and sizes, depending on the desired form and function of the unit.

Most plastics sheet materials, like acrylic or lexan, come in sheets that are 4'x8′ or larger. Having a CNC Router with at least a 5’x12’ table ensures maximum material yield when nesting, and provides greater flexibility in the size of parts that can be manufactured.

For those looking into mass-production, other machine styles, such as the dual-table, twin spindle, or automated systems, will offer higher-throughput capabilities. A machine's style and quality can have a large impact on cycle times and the edge finish of your parts; you may invest a little bit more, but it will ultimately reduce your cost per part.

Waterjets and even laser cutters can also be used to cut a lot of these plastic PPE components.

Suggested Tooling

The last thing to consider if you are trying to machine these dividers and partitions is making sure you are using the appropriate tooling. All router bits are not created equal when it comes to machining plastics. Using tools at proven feed rates will ensure quality edge finish and prevent issues like melt back, chatter, or cracking. Some bits are designed for machining hard plastics, soft plastics, or entirely different materials. The helix of the tool, the number of flutes, along with the rake angle, coatings, and other technical features all will affect the products you produce. Working with a tooling expert (which CR Onsrud has on staff to consult) is suggested to help get you started in the right direction.

Check out the video below to learn how these sneeze guards and partitions are being made. In addition to this video, below is a tool list and equipment list to help those looking to become a manufacturer of these partitions.

Custom Sneeze Guards

Sneeze Guards (and many other items in the store like the checkout desks and store displays) are made on a CNC Router, such as the American Made, M-Series CNC Router by C.R. Onsrud.

Typically, these dividers will be machined from a sheet of polycarbonate, acrylic, plexiglass, or other types of clear plastic polymer.

To hold up the dividers, feet or stands are then needed. These stands are also machined on CNC Routers and can be made of many different types of materials as well, depending on the type of look the business wants. Some companies will opt for a simple plastic foot for a more portable design, while others may choose to make a stylish or heavier base out of aluminum or wood to have a more permanent presence.

Other dividers are simply attached to existing counters or hung from overhead. Additional types of protective shields like Intubation Boxes, Splash Guards, food shields, barrier shields, face shields, and more, can also be made on CNC Routers. These items are made through similar processes out of much of the same materials.

Suggested Tooling

Another thing to consider if you are trying to machine these dividers and partitions is making sure you are using the appropriate tooling. All router bits are not created equal when it comes to machining plastics. Using tools at proven feed rates will ensure quality edge finish and prevent issues like melt back, chatter, or cracking. Some bits are designed for machining hard plastics, soft plastics, or entirely different materials. The helix of the tool, the number of flutes, along with the rake angle, coatings, and other technical features all will affect the products you produce. Working with a tooling expert (which CR Onsrud has on staff to consult) is suggested to help get you started in the right direction.

CNCCookbook's G-Wizard Calculator is ideal for determining your best Feeds and Speeds.

Tooling List

O-Flute, High Helix - 3/8in - Specifically designed for Acrylic to provide a nice finish with upward chip removal (at medium feed rates).

https://www.cronsrud.com/store/63-535-3-8-inch-1-flute-sc-upcut-spiral-o-flute-for-acrylic.html

O-Flute, High Helix - 3/8in - Specifically designed for soft plastics to provide a smooth finish and upward chip removal (at medium feed rates).

https://www.cronsrud.com/store/63-780-3-8-inch-1-flute-sc-upcut-spiral-o-flute-soft-plastic.html

2-Flute, Low Helix - 3/8in - Great for thin or less rigid plastic. Two flutes allow for faster feed rates.

https://www.cronsrud.com/store/52-664-3-8-inch-2-flute-sc-upcut-spiral-o-flute.html

2-Flute, High Helix - 3/8in - Great tool for edge finish on thicker or more rigid plastics. Two flutes allow for faster feed rates.

https://www.cronsrud.com/store/52-728-3-8-inch-2-flute-sc-upcut-spiral-o-flute.html

CRO-280 (2F Router, High Helix) Great tool for Acrylic, also works well in the harder more rigid plastics.

https://www.cronsrud.com/store/cro-280-1-4-sc-de-up.html

Pro-Tip: Two factors that greatly help while cutting plastic are chip evacuation and compressed air on the tool. Try and keep the chips away from the cutting tool so that you are not recutting chips, and keep the tool as cool as possible. This helps with speed, finish, and tool life.

Cleaning and Disinfecting Medical Face Shields and Sneeze Guards

You will want to clean and disinfect your PPE before it is packed for shipping as part of your quality assurance. The University of Iowa medical department recommends these cleaning products:

- Sani-Cloth AF3 Wipes (grey top)

- Sani-Cloth Bleach Wipes (orange top)

- Virex 265 Spray

- Commercially available disinfection wipes from your grocery store, such as Clorox wipes

Personnel involved in the manufacture of PPE should be wearing nitrile gloves, face shields, and masks as well.

PPE Suppliers: How to break into the PPE market

To break into the market, you'll need to either have an established eCommerce business that is suitable to sell your PPE Products over the Internet, or you'll need to go call on potential local customers who are in need of what you have to offer.

I'm going to focus on calling on local customers here.

Start by making a list of the likely candidates. Who needs PPE Gear in your local market?

Sneeze Guards are going to be needed by restaurants, bars, and food shops of various kinds. But don't forget, any office where someone has to walk up to a counter and deal with someone behind the counter might benefit. That makes for a much longer list.

You want to deal with mom and pop stores unique to your area. The Big Chains are going to need approval from Corporate to make a decision. Easier if you can sell directly to the decision maker and not have to navigate a beaurocracy.

Next, you need to decide whether you're selling custom products or something you manufacture to your own design. The custom business is nice because your offering is unique-it is customized to precisely fit your customer's shop and needs. Custom sneeze guards are a great opportunity, and custom Custom Restaurant Sneeze Guards are something you may do well with. Let's use that as our example.

Custom Restaurant Sneeze Guards

Put some things together that you'll take on your sales call:

- Samples. Whether we're talking Full Face Shields or Sneeze Guards, some samples that are easy to carry and show the high quality of your products will be helpful. BTW, a leave-behind sample that has your customer's logo or name on it can be very persuasive.

- Business Cards are always needed for sales calls. Some sort of brochure or folder with handouts may also be helpful as a leave behind.

- If you're going to be doing a custom sneeze guard, bring your tape measure and some graph paper so you can sketch the intended measurements quickly. Perhaps some sample hardware so they can choose what sort of trim would also be helpful.

Once you've got your sales kit together, get on the phone and see if you can get some meetings. You'll have to track down the owner, but the key to that is to find some other owners of similar businesses. They will often know each other around town.

You first need to sell them on the idea of taking a meeting and then once in the meeting on the idea of buying from you. Over time, you'll refine your pitch and get better at snagging meetings. Your close rate on sales will increase.

Here's a thought. There's probably a local restaurant supply in your area. See if you can partner with them to sell your goods.

Medical Offices

Use the same tactics for medical offices. Find someone who knows the doctors around town and use them to introduce you. Don't forget chiropracters and other similar professions. You'll do better with smaller offices versus the big hospitals, though if you have an "in", don't hesitate to use it. Networking is the often the best way to get your foot in the door.

What Else?

Any walk-up counter could potentially use a Sneeze Guard...

Remember, any business with a walk-up counter may need Sneeze Guards, not just restaurants and medical offices. And, some organizations may want sneeze guards that are more aesthetically attractive. Retail, legal offices, and real estate offices are examples, and there are many more possibilities.

Manufacturing PPE FAQ

What Types of PPE are Needed for Covid-19?

Personal Protective Equipment to reduce the chance of infection include gloves, scrubs, masks, face shields, and sneeze guards. Of those, CNC shops can easily manufacture face shields and sneeze guards.

What is a Sneeze Guard?

Sneeze guards are partitions that can sit on counters, be hung from above, or be free standing from the floor. They're clear and block aerosol droplets from moving between people and food or other materials.

What Should I Use to Clean Face Shields and Sneeze Guards?

The University of Iowa medical department recommends these cleaning products:

- Sani-Cloth AF3 Wipes (grey top)

- Sani-Cloth Bleach Wipes (orange top)

- Virex 265 Spray

- Commercially available disinfection wipes from your grocery store, such as Clorox wipes

What is the Best Plastic to Use for Face Shields?

Acetate and PETG are the best plastics for face shields. Polycarbonite is used too, but is less suitable because it is brittle and cracks easily.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.